Using no-touch tools hand lifters for load guiding materials handling is an excellent choice for increasing safety in the workplace and preventing hand injuries.

Listed are some of our top no-touch-tools for the manufacturing & fabrication industries:

Fixed Hand Lifter and Hand Lifter 60-M

These hand lifters are the most popular no-touch hand-lifting tools.

While both the Fixed Hand Lifter and the Lifter 60-M are available with 106kg of force, the Fixed Hand Lifter also has an option of 177kg of force and has better wrist control, making it a safer choice for handling.

Hand Lifter 60-CE (Cordless Electric)

The Hand Lifter 60-CE is perfect for sheet metal workers handling large volumes of thin gauge metal.

This speedy magnet will pay for itself in no time. The Hand Lifter 60 Cordless Electric comes with a holster, a charger and two lithium batteries. Each charge is good for 1000 lifts.

Dual Hand Lifter

The Dual Hand Lifter allows two people to handle material heavier than one person is allowed to lift. It can also allow one person to safely handle material that is light, yet dimensionally large.

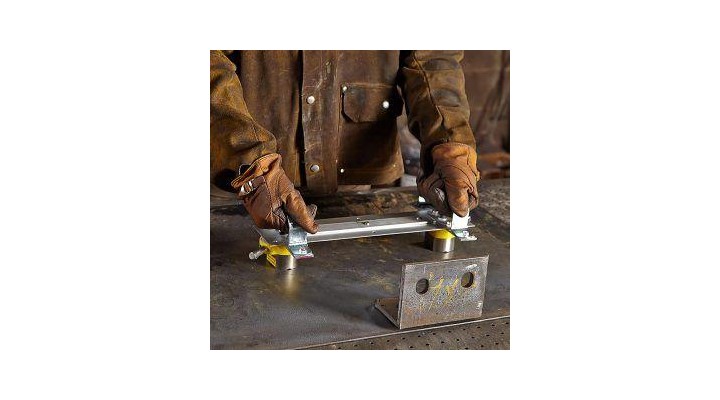

Mag-Reach 400

Our newest no-touch tool released in 2021, the Mag-Reach 400 is specifically designed for use on burn tables.

Something that makes the Mag-Reach 400 special is that the strength of the magnet breakaway force is 181 kg, and the extendable handle gives the option to pick up the middle of skeleton/nest without extending over the burn table. It also gives the option to walk on the burn table and pick up cut pieces from the burn table without bending, reducing risk of both hand and back injuries, which are the most common injuries in the workplace.

-160x160-state_article-rel-cat.png)