By making general statements, OHS allows employers the freedom to set up aisles to best accommodate the functions of their facility. The following are some basic guidelines that you are required to meet.

Aisle Marking

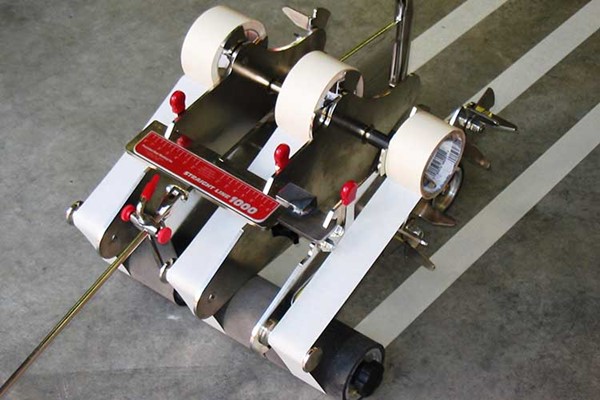

The regulations require that permanent aisles and passageways must be marked, but do not define how it should be done. A common method for marking is by using yellow paint or stripes. OHS designates yellow as the “caution” colour, to be used for marking physical hazards such as stumbling, falling or tripping. Painted yellow lines are usually recognized as the most convenient and inexpensive way to mark aisles since the lines normally last several years before repainting is necessary. Where painted floor markings are impractical, other methods that can be used include marking pillars, powder stripping, flags, traffic cones or barrels.

ANSI Z535.2 (American National Standard for Environmental and Facility Safety Signs) Safety Color Code also defines “safety yellow” as the identification of CAUTION. It requires the use of solid yellow for maximum contrast with the particular background and it designates yellow as the preferred method for traffic markings.

Aisle Width

There is not a “one-size-fits-all” width for aisles and passageways in the OSHA standard, but there are requirements in some specific instances. These include requirements that aisles be at least three feet wide inside storage rooms containing flammable and combustible liquids, and that 28 inches is the minimum width for emergency exit access.

OHS general requirement for aisles and passageways is that “sufficient safe clearances” must be provided where mechanical equipment is used. The width will vary depending upon how the aisle is utilized in the workplace, as aisles that forklift trucks or other mechanical equipment use will need to be wider than aisles for pedestrian traffic.

For more information on how we can help with your Floor Marking requirements contact us.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)