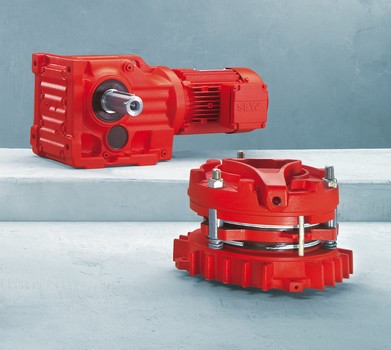

Compact and robust in design, the company's brakes are extremely quiet in operation, boast particularly short response times at both switch-on and switch-off, and have a fail-safe design that ensures the brake is always applied when de-energised.

The SEW brake offering features a spring-operated pressure plate that provides torque against the brake disk. The brake is based on a patented two-coil design comprising an accelerator coil and a holding coil operated by an AC-to-DC intelligent rectifier circuit that can be either cabinet-mounted or integrated into the motor terminal box. When energised, the accelerator coil creates a strong magnetic force that counteracts the spring force and releases the pressure plate from the brake disk in a very short time. Once the brake has released, the holding coil retains the brake in the open position while the motor is running.

According to SEW-Eurodrive Victorian Sales and Product Manager, Darren Klonowski, the accelerator coil design allows for particularly short response times at switch-on. "This helps minimise start-up heating in the motor, reduces energy consumption, and also increases the number of cycle times at which the motor can operate," he said. "Similarly, SEW-Eurodrive's brakes benefit from short response times at switch-off, which facilitates shorter braking distances, high repeat accuracy and an elevated degree of safety. These, plus the fail-safe feature, ensure that SEW's brakes are particularly well-suited to horizontal and vertical applications, such as hoisting."

A range of brake torques can be configured to suit a specific motor type. This is achieved through different brake sizes, spring type and quantity installed. The brake torque can be varied to suit the application requirements, and range from a very low torque right up to 300 per cent of motor torque. Brake operating voltages can also be varied to match the control requirement, and span from 24V DC to 500V AC.

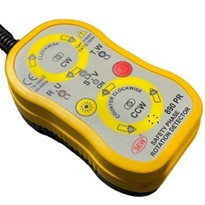

To cater for specific applications, a range of other rectifiers and auxiliary options are available for control and activation of the brakes. This includes a range of current and voltage relays that integrate with the rectifiers to achieve faster brake reaction times-a useful feature for hoisting applications and safe load handling.

In critical applications where brake activation and/or wear must be known, SEW brake offering can be fitted with sensors to provide feedback to a high-level control system, PLC or frequency inverter. "The customisable nature of SEW's brake offering means that the end user's specific requirements can be met exactly," said Klonowski. "Whatever the electric brakemotor application, we pride ourselves in being able to provide Australian industry with the premier solution to meet its needs."

-160x160-state_article-rel-cat.png)

-205x205.jpg)