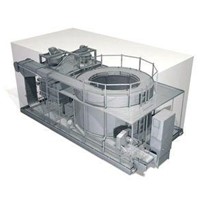

eaturing a new size when shipping and installing, the latest version of the GC40 has been re-designed to overcome challenges associated with narrow facilities and cramped spaces. Instead of being delivered as a single unit, the freezer now comes part assembled with smaller sections adapted to tight factory conditions.

With floorspace often at a premium, the physical task of bringing a new spiral freezer into a protein processing plant has – until now – been fraught with difficulties. The sheer size of a pre-assembled freezer meant that, in facilities where space was limited, getting the machine in place and installed was a real challenge.

With the introduction of its latest version, installation of the GC40 has been significantly simplified. Now delivered as part-assembled rather than a pre-fabricated single unit, the new GC40 is designed to be assembled on-site within a small area, making life easier for customers, explains Torbjörn Persson, JBT’s Director of Product Line Management for Frigoscandia Freezers.

“The GC40 used to be delivered as a single piece including the enclosure, which made it challenging for customers with narrow factories or cramped spaces to get the machine in position and installed,” he says.

“Previously, the lowest height started at 3.1 meters for the machine and could be up to 4 meters, which could be a real challenge for existing factory doors. Although the assembled freezer will continue to have the same dimensions as before, we have made the parts smaller to be able to bring it in to tight factory conditions.”

Winning features

An upgrade on what was already the most compact, hygienic and efficient self-stacking spiral freezer ever made, the GC40 is capable of freezing capacities of up to 1,000 kg/hour.

Featuring unrivalled energy efficiency and freezer power consumption from five kW, the GC40 also includes the unique FRIGoBELT® Nova self-stacking belt, which forms a closed freezing zone with no risk of products moving by horizontal airflow. Further, the GC40’s FRIGoDRIVE® system removes the need for a center drum with no supports or rails to cause jamming.

Hygienic-by-design, the freezer features no stationary parts in the belt stack that can complicate cleaning, plus an open profile design to minimize dirt traps.

-160x160-state_article-rel-cat.jpg)

-205x205.jpg)