They can analyse the results of the nightly measurements of their fresh water pipelines in a few minutes and make important decisions for the day. Are there any new leaks in the system? Using the information found, the water engineer can send his workers to precisely those points that the leak detection system has indicated.

In the past regular field measurements had to be carried out manually

Without network monitoring finding leak was like searching for a needle in a haystack. Oftentimes the person responsible knows how much water is lost each year (frequently it is 25% of total consumption and more). But finding out where the leaks are located often needs the help of coincidence or a painstaking physical check of the pipeline network. Sometimes an alert member of the public reports a leak when they see water seeping out of the ground, sometimes an employee finds a suspicious spot during routine checks with the listening stick or noise logger. Weeks or months then often pass between the occurrence of the leak and its exact localisation. In the worst case, the small leak has become a bigger one or even a burst pipe. Depending on the nature of the ground, the water escaping from the pipe finds its own route over the course of time. This can lead to the undermining of roads or damp cellars.

The entry of “Big Data” and “Cloud-Computing” into water supply management

The principle of permanent leak monitoring is known from many other application areas: a large number of sensors is distributed so it covers a large area of the system to be monitored, the measurement data and the associated information is collected at a central point and processed and analysed with intelligent algorithms which deliver precisely the results that are of interest to the user. Whether this is the pollen count or weather forecasts, intelligent car park management and Smart City: “Big Data” and “Cloud-Computing” here are not about personal data, but about the most efficient way of collecting and processing sensor information. The advantages are obvious:

- Systems are comprehensively, completely and automatically monitored

- Relevant results are available quickly and in a pre-processed form online or by email, without even having to be on site

- Automatic alarms reduce risks of damage to people and infrastructure

- Leak-related changes can be more easily identified by continuous measurements, and erroneous measurements (outliers) can more easily be identified

- Complex situations can be automatically synthesized to the relevant information and reports for management and for the repair teams automatically created

Award-Winning Leak Detection Technology by Gutermann

Thanks to the product platform ZONESCAN, Gutermann has established itself worldwide as a technological leader and has already won nearly a dozen technology awards. Over 200 cities worldwide are now equipped with the Gutermann ZONESCAN ALPHA permanent leak monitoring system, sometimes covering parts of a city and sometimes with comprehensive coverage. The first systems in Germany were already installed at the start of this decade. Karl-Heinz Beißwenger of the Eislingen Zweckverband said “We tested ZONESCAN ALPHA for the first time in 2010. The losses through leakage in the test area were reduced by so much after only a few days that the purchase cost of the system was recouped after only three months.” Since then the coverage in Eislingen has extended to nearly 1,000 measurement points. Frank Tantzky, the director for Asset Service at Albstadtwerke reports that in the area of Stetten administered by him there was a reduction in network losses of nearly 40% in the first year alone and of nearly 50% in operating costs. Losses of water in the town of Aulendorf were so high that purchasing a ZONESCAN ALPHA system for the entire water network was considered necessary on the grounds of costs, and since then crucial savings have been achieved. The cities of Trier and Benningen have also recently chosen permanent network monitoring with correlating noise loggers from Gutermann. In Switzerland, where Gutermann is based, dozens of communities are now completely covered by this sensing equipment. Many Swiss water engineers see having their own water networks under control as a “Public Service” and so requiring the standards of quality of public services. Since 2015, the city of Lyon has been monitored over a large area by the world’s largest water supplier Veolia using over 6,000 ZONESCAN sensors, whose data is collated by Veolia’s AMI network and transferred to its own control system.

More Efficient Data Transfer by the “Internet of Things”

Everybody talks about the “Internet of Things” these days. But what does that actually mean for sensor technology in the water industry? Correlating noise loggers pose particular challenges to data transfer: First of all, you must be able to transfer the data from the narrow chambers at some depth. Second, the quantities of data needed for the correlation are much greater than those required for normal noise loggers or even water meters. And third, precise synchronisation of noise recordings (below one millisecond) is also needed for correlation (see box). To meet all three conditions, specially optimised radio systems had to be used for data transfer up until now, partly involving so-called radio repeaters (as for example in ZONESCAN ALPHA installations). Due to the rapid progress in the field of cellular LPWLAN-networks (Internet of Things), these networks can meet at least the requirements for data quantity and transfer quality. Gutermann is working on a new generation of IoT-loggers, which will also satisfy the requirements for synchronisation in a second phase. Here, the announced comprehensive implementation of LTE cat. NB1 (also known as NB-IoT) and LTE cat. M1 in many cities should be emphasised. These will allow the radio solution to be done away with, without impacting the quality of the results. Also the installation and maintenance efforts and expenses will be greatly reduced. This will make the decision in favour of a permanent monitoring system even easier for many water companies.

Convergence of the der Permanent and Mobile Applications

Since comprehensive coverage with permanent leak monitoring may not always make sense financially or operatively, permanent leak monitoring and mobile network surveying can be skilfully combined today. With Gutermann, more and more data from individual devices like correlators and loggers can be uploaded into the same cloud solution. Thus, all measurements and their results can be permanently stored and clearly displayed graphically in the same user interface with Google Maps mapping facilities. Leak detection work has become more transparent and reproducible. More and more of these instruments are simply controlled by tablets, using attractive apps and automatic position display on free downloadable maping material. The installation of permanent systems will soon also be possible simply using app and tablet or smartphone. Alarms about potential leaks or warnings about function faults can be quickly and conveniently investigated.

Large Supply Pipelines are Now Being Monitored with the Help of Hydrophones

The latest development in the area of monitoring drinking water supplies is the extension of the existing system to larger transmission pipelines, so called trunk mains. The demand for this is especially large, but so are the technical challenges. Trunk mains connect the water works or reservoir with the distribution network. The pipe diameters are typically 300 to 1200mm. Whilst the damage caused by a leak around the distribution network or the house connections will usually remain negligible, the consequences of a failure in a trunk main could affect whole city districts or industrial areas. This is when early warnings and alarms are particularly needed.

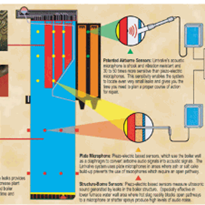

To be able to detect even the smallest leaks in pipelines of these dimensions over long distances, instead of the accelerometers fixed to the pipe wall from the outside, highly sensitive hydrophones are installed so that their membranes measure the acoustic signal directly in the water. The hydrophones are installed 600 to 800 metres apart. Gutermann for example is currently launching the product HISCAN, the development of which has taken five years and was partially funded by a grant of the Federal Ministry for Education and Research (BMBF). HISCAN enables permanent monitoring of main transmission pipes (or plastic supply pipes) through daily correlation of noise data. The first trunk main hydrophone loggers have already been installed in France, Australia and Saudi Arabia.

The Future is Full of Promise

It is easy to imagine the data from the leak detection system being used for other purposes and combined with other data sources in the future: statistics about the frequency of leaks in specific supply pipeline sections could be used to inform decisions about necessary investment. In combination with smart metering (measurements of usage and through-flow) one can quantify water losses for individual leaks more precisely and so prioritise them. Alarms could be used to directly reduce the network pressure to limit subsequent damage. The more data is available, the more such a permanent monitoring system can be developed into an expert system that also allows projections about possible future leaks or about the remaining lifespan of supply pipelines. Gutermann has already been researching all these topics and will integrate appropriate solutions into their existing cloud software.

“Gutermann has been known for years as an innovative technology company”, says Frank Tantzky of the Albstadt works. “We are excited about the future product innovations and we will integrate useful technological enhancements into our network maintenance so that we can respond quickly and effectively to water losses even better in future.”

How does Permanent Leak Monitoring work?

When water escapes from a pipe, there are structural vibrations which spread along the pipe walls and in the water and spread out to both sides of the leak. Special noise loggers (accelerometer sensors) are attached magnetically to the outside of the water pipes. They transmit their acoustic measurement data daily to a server which analyses the data and passes the results via a secure internet connection to the water works. In the ZONESCAN ALPHA system of the Swiss company Gutermann with their R&D and production facilities in Baden-Württemberg, the measurements are taken with a very high time synchronisation. Using the laws of sound propagation the measurement data from the different noise loggers can be correlated. This has the advantage that the leaks can be located with very high precision, and false interpretations (false alarms) can also be reduced significantly. Furthermore, correlations are around 30 times more sensitive than normal noise level measurements and thus suitable for plastic networks. They frequently enable the detection of small leaks as they begin before they cause greater damage. The daily measurements of the noise loggers consist of correlation measurements, the noise spectrum and a noise level distribution. This information is linked to historical values in the leak database by an expert system on the server for calculation of the leak probability. Based on the correlation, the position of leaks can typically be determined with an accuracy of less than a metre and shown with an icon on a Google Map in the web browser.