In addition to managing and maintaining the local distribution assets in Albstadt, Albstadtwerke operate and maintain two more potable water distribution networks, seven natural gas distribution networks and an electricity supply.

Albstadtwerke is efficiently run with 80 employees for the entire operation and construction of our networks and facilities. It has been a corporate policy for many years to continuously evaluate current methodologies and introduce new innovative methods in leak detection and trenchless pipe installation.

In this paper we will share information about our vast experience with innovative technologies in reducing water loss and information about our latest system that permanently monitors the network and alerts us as soon as a leak appears.

The Challenge

The Albstadt regionh is spread across three valleys and has a height variation of 400m. This geographical landscape creates a number of operational challenges, including:

- A large number of different pressure zones

- Long sections of trunk main

- Long distances for maintenance staff to drive to reach the extremities of the network.

Approximately 50% of the water supply comes from our raw water catchment and is processed in several stages at our water plant to produce high-quality drinking water. The other 50% is purchased from a total of three suppliers. We are about 80km away from the Lake of Constance, which is one of the biggest lakes in Europe.

Our current Non-Revenue Water is 20% (500,000 cubic metres), which has increased from 10% five years ago. The increase in the NRW percentage is due to a 50% reduction in total consumption; our water loss has remained constant.

The ground is limestone, which means that almost no leak is visible on the surface as there is always good drainage. We have had massive leaks of 25L/S disappear underground. Our first investigation was in the Braunhartsberg reservoir zone. This zone consists of 52km of pipework with a mixture of cast iron, UPVC and ductile iron, and it contains most of the factors that make leak detection difficult.

Water Loss Innovations

Our first strategy to improve network efficiency was to install a flow meter on the reservoir outflow and have the data sent to our office on a daily basis with alarms to advise us if there was an increase in minimum night flow (MNF). This is shown in Figures 3. In addition to providing an alarm warning us the MNF was rising, we could also quantify the size of the leak.

Leak detection was performed by sending a team out in a van to deploy noise loggers with radio communication and then download the data in a driveby survey the following day to localise the leak position and use a ground microphone and correlator to pinpoint the leak.We have been using this equipment for many years and we have found that only loggers with radio communication could be used efficiently. The loggers are mounted directly on the pipeline with a magnetic connection to provide a good sound recording. It would often take this two-man crew five to ten days to find the leak in this large zone, driving an hour each way every day.

The next strategy made to improve efficiency was to install additional flow meters within the zone to localise the leak position to a smaller area within the zone, and reduce the amount of time spent searching for the leak.

We were not measuring or analysing total flow into sub-zones, we were just looking at significant changes in daily water flows to localise the leak positions.

Our Next Improvement – the Optimal Solution?

With the previously identified systems, Albstadtwerke were able to achieve good results. However, there was always still a certain amount of effort to carry the measured data to the office for any detailed analysis and then send a crew to pinpoint the leak before the leak is repaired.

Because of Albstadtwerke geographical situation, a lot of time was wasted driving back to the office to analyse the data and then back to the field to pin-point the leak.

Therefore, we decided to introduce a system that transmits the data every day to the decision makers in the office to reduce the response time and travelling time.

Noise loggers have been deployed through the network; as previously, they record the noise levels and sound. If pre-determined limits are exceeded, the logger sends a leak alarm to headquarters. Each logger is connected by radio with a repeater. All repeaters are in contact with a data collector (ALPHA), using radio to collect the data from the repeaters and GPRS to send the data to the server. We then have immediate access to the measurement data and can make a leak assessment.

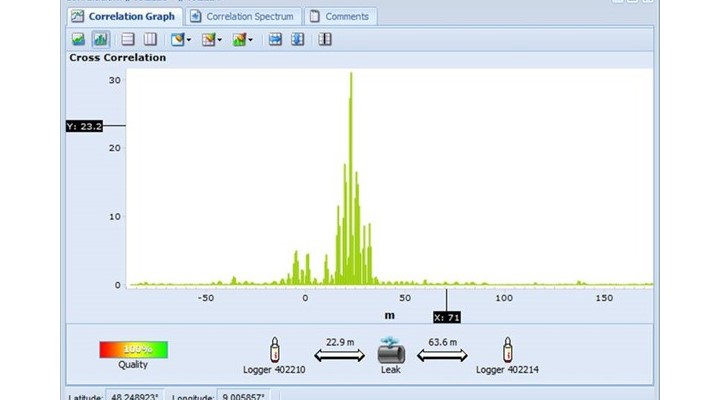

By modeling the system with geographic network data, the loggers are able to recognise their position in the network and create the relationship to its “neighbouring” loggers. This fact allows a direct correlation between the loggers and, thus, a quite precise determination of the leak.

The installation was fast and economical, without any structural changes to the distribution system.

Eighty loggers, 42 repeaters and two Zonescan ALPHA were deployed in the Braunhartsberg pressure zone enabling fully automated leak monitoring of the entire zone, consisting of 52km of pipe.

Assessment

Communication reliability: We found the communication to be very good, without the need to install an antenna close to the surface.

Batteries lifetime: We operate in a temperature range from –30°C in winter to +30°C in the summer. In 12 months of operating the Zonescan, there have been no problems.

The Monitoring Platform

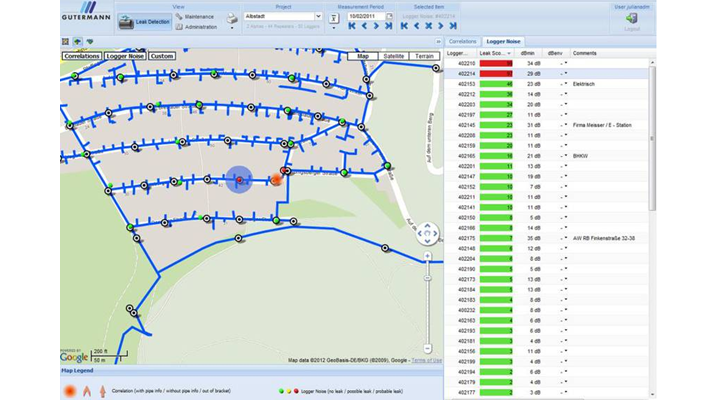

The data is hosted on the Gutermann webserver and accessible via log-in to the Zonescan net software. There is mapping, amplitude distribution graphs, frequency spectrum and correlation data in this software platform.In the Zonescan net software; the green, orange and red dots are the loggers. They are colour-coded green for no leak, orange for possible leak and red for probable leak. The fuzzy orange dot is a correlated leak position.

It is also possible to show the loggers in a satellite picture; this provides better orientation. When this particular leak appeared it was identified with correlations from over 15 logger combinations and we repaired the leak in record time, it started on February 9 and was repaired on February 10.

Albstadtwerke can identify mechanical noises, which reduces the amount of time wasted searching for noises that are not leaks.

Conclusions

With this technology Albstadtwerke have been able to continue to maintain our MNF to 0.4L/S, with an average run-time of a leak event being 1.5 days, enabling us to reduce our water losses to lower levels than ever before. In addition to this we have reduced the effort and cost of localisation by 98%.

With very good maps of the pipeline network the Zonescan produces a precise location of the leak.

Considering the excavation cost is €3,000, we still confirm the leak position with a ground microphone before digging.

We had no communication problems during a particularly cold winter, with a thick layer of snow on the ground.

We found small leaks that our experienced leakage team would not have discovered, and the leak hunters tell me they can hear the worms cough!

Since the paper was presented at the Global Leakage Summit, Albstadtwerke has started installing the equipment over significantly increased area of their network. And they are still expanding...

Read the rest of the case study here

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)