Innovative & Robust Designs

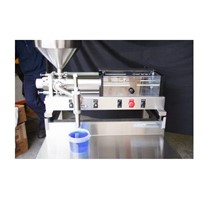

Your Packserv Manufacturing volumetric filling machine is designed with the highest grade of materials and finishes to ensure minimal maintenance is required for continued operation. The innovative and robust design eliminate the necessity for an extensive preventative maintenance routine traditionally seen in manufacturing machinery. Extended downtime for extensive preventative maintenance and be costly for a business if it is needed regularly.

All controls, valves and pneumatic cylinders on volumetric filling machines require NO lubrication and all other dynamic parts are either self-lubricating or only require an infrequent application of lubricant.

The rotary product valve featured on a volumetric filling machine is not suited for exposure to high temperatures (>60°c), caustic or high pH products. In the event that the product being filled meets the prior criteria then there are alternate materials and solutions available.

Accurate Seal Selection

All seals used in a filling machine are selected on a case-by-case basis however the seals are traditionally Viton (fluoroelastomer) based and selected for their minimal friction and high chemical resistance properties. In the event of a chemically aggressive product being filled, the longevity of these seals will be dramatically reduced. To combat this, there are a variety of alternate materials available to have your seals designed in to provide the best possible life and performance of these seals. In the event of a specific chemical being used which reacts with Viton we request the Safety Data Sheets of your product to ensure accurate seal selection is made.

Daily Maintenance Requirements

Daily maintenance simply involves ensuring to drain the air filter bowl of any accumulated dirt and moisture. In the instance of frequent accumulation of moisture this can indicate issues relating the air supply and we would recommend inspection of the air compressor unit. In addition to this, a visual inspection of the machines joints/clamp points, rotary valve and product cylinder to ensure no escape of product is present is suggested. If this occurs common issues are the breakdown of an internal seal.

Monthly Maintenance

Monthly maintenance includes the lubrication of stainless steel shafts with bearing grease in the instance of bearings travelling on the shaft. Pneumatic grease should be applied to the stainless steel shaft of the main pneumatic drive cylinder. In both instances only a light layer should be applied. Different environments may require more frequent applications.