1st Reference letter written by the company's Maintenance Manager

"We have been incurring serious maintenance problems with our fleet of 200 taxi vehicles. On average, we have had 13 cars per day in for an engine overhaul or replacement. The down time, parts and labour costs have been excessive. In an effort to reduce these costs we began to experiment with various oil additives in the hope of reducing wear and improving performance.

We tested Slick 50, T-Pluss, Microlon, Duralube, System 48 and a few others. Compression readings were taken prior to the adding of the various products mentioned. After two or three days no improvement in compression or overall performance was noted. In fact, several of the tested engines incurred build-up, pitting and/or had clogged oil filters. Our drivers reported that there were no fuel savings or improvement in performance. We still had an average of 13 cars down each day.

We then tested your Bi-Tron Engine Treatment in nine of our units. To say the least we are quite pleased with the results. Before adding Bi-Tron, the compression reading of each vehicle was taken and found to be between 90 and 150. All had engines with problems or expected to have a maintenance problem in a short time, with poor performance and fuel consumption.

The engines were treated with Bi-Tron according to instructions and road-tested for two days with the following results:

- Compression readings ranged between 149 and 154 (Note: 154 is equivalent to that expected from a brand new engine)

- Increased power and performance were reported by the drivers

- The Bi-Tron treated taxis ran quieter and smoother

- The average operating temperature was reduced by 20 degrees (190 to 170)

- Drivers reported distance improvement

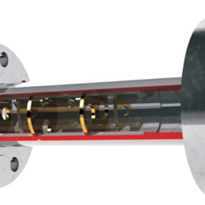

- An engine treated with Bi-Tron was disassembled and inspected. It was found clean, had no build-up and the surfaces appeared to be polished

2nd reference letter written by the Maintenance Manager 6 weeks after using Bi-Tron products

"We feel an update on the use of your Bi-Tron is in order. As you know we used to have an average of 13 cars down for engine overhauls or replacement each day. Since using Bi-Tron (now going on seven weeks) we have not had one engine go down. When considering these vehicles are driven an average of 500 klms per day, under the most severe of conditions, the results are nothing less than remarkable!

We had one engine lose all its oil. The driver was unaware of the situation because the oil pressure light was not working, and drove back to our workshop without incident. Our mechanic, after noticing that there was some oil dripping, found that there was no oil in the sump and that the oil pan was slashed.

The pan was replaced, new oil added and the engine started immediately. This taxi is still in daily operation"

After several months we have inspected 5 engines in the cars we previously had inspected.

Before Bi-Tron:

Sludge and carbon build-up was always found on cylinder walls of all our car engines.

Usually we had to replace the oil filters every 2,000 klms with every oil change. (because of the harsh stop-and-go driving conditions).

After Bi-Tron:

With Bi-Tron added, the cylinder walls are always clean from any build-up, and look highly polished.

With Bi-Tron added, the oil filters are clean of any sludge or carbon deposits, in spite of the fact that oil change intervals were increased from every 2,000 klms to every 10,000 klms.

Before Bi-Tron:

There was heavy carbon deposits on the piston tops, and, on and around piston rings which caused the rings to "freeze" and even break. On the average, we had to overhaul engines every 60,000 klms because of the harsh stop-and-go driving conditions.

After Bi-Tron:

These 5 engines were taken apart, first time after 60,000 klms and the second time after 150,000, with oil and filter change intervals at every 10,000 klms).

Because of the adding of the Bi-Tron Fuel Conditioner, the piston top, is clean of any deposits.

Due to the adding of the Bi-Tron Engine Treatment, the piston-skirt and rings are completely clean of any deposits, and the piston-ring-blades are highly polished.

Due to the Bi tron Fuel & Bi tron Engine Treatment added, the oil in the sump hardly discolours between oil changes.

As a result of the above, we are now using your product in our entire fleet"

Money can't buy the insurance you get by adding Bi-Tron treatment to your engine and machinery.

For more information on we can help your fleet please call or use the email enquiry for a direct reply.