Trusted for value

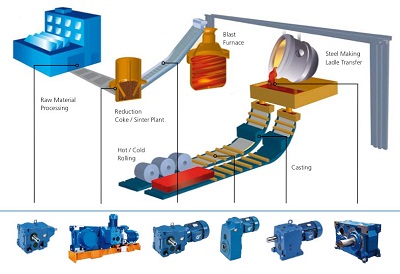

Because of the harsh environment with changing loads combined with high ambient temperatures 'classic' roller table motors are used.

Some manufacturers and users still consider 'ring-fin motor' to be an established part of a rolling mill.

Three-phase motors with horizontal cooling fins also worked satisfactorily in the last years in different parts of rolling mills.

What matters is that the different loads and required starting torques (acceleration) and break-down torques for a roller table are absolutely considered in the calculations. Besides it can happen that a steel slab is blocked and that only few rollers are accelerating the slab, which means that these drives will be overloaded.

The major task of roller table drives is the deceleration and acceleration of the transported steel slab, profile or tube.

In the transportation phases with constant speed relatively little power is needed. The geared motors in steel plants, especially the mill area are calculated and selected according to the high acceleration load and shock loads with a high service factor, based on the acceleration torque.