In the realm of timber construction, handling heavy and cumbersome materials like boards, sheets, and cross-laminated timber (CLT) requires innovative solutions. HolzBauWerk Schwarzwald utilizes Schmalz's vacuum technology to transport these materials effortlessly and automatically, significantly improving production efficiency. Their use of multiple suction spiders not only facilitates the movement of boards but also handles components weighing several tons.

Wood Variety and Production at HolzBauWerk

Located in Seewald, HolzBauWerk Schwarzwald, established in 2021, specializes in the production of cross-laminated timber (CLT) using local spruce and Black Forest silver fir. With a 15,000-square-meter covered area, the company manufactures 20,000 cubic meters of CLT annually. Their products are used in timber construction projects across Germany, Switzerland, France, and the Benelux countries.

Automated and Efficient Production

Since commencing production in September 2022, HolzBauWerk employs around 40 staff members in their fully automated system for creating solid wood sheets. These sheets consist of at least three layers of cross-laid softwood boards bonded together and range from six to 32 centimeters in thickness, up to 3.5 meters wide, and a maximum of 16 meters in length. They are used for manufacturing wall, ceiling, and roof elements. CLT, introduced in the 1990s and popularized since the 2010s, is valued for its sustainability, stability, fire protection, thermal efficiency, and earthquake resistance.

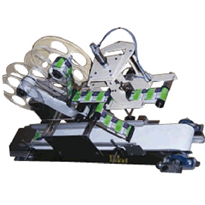

Advanced Handling with Suction Spiders

To maintain high-quality standards, HolzBauWerk dries all wood in-house and sorts it based on visual and technical criteria. The SSP suction spider from Schmalz, equipped with five FMHD area grippers, lifts and stacks boards in a buffer store with precision. An external vacuum generator provides the necessary suction power, and the spider’s integrated system monitoring and sensors ensure reliable operation. The FMHD grippers handle heavy and irregular workpieces effectively, accommodating knotholes, warping, and unevenness.

For CLT production, another suction spider with four FMHD grippers destacks board layers. This fully digitalized process produces wooden boards of varying thicknesses and sizes in batch size 1. Defects are removed, and a finger-jointing line connects the timber into continuously cut boards, which are then sawed to length and glued together. This process ensures closed surfaces, high airtightness, excellent fire protection, and optimum strength.

Precise and Safe Handling

A third suction spider, also with FMHD grippers, alternates between length and cross layers in a buffer store and feeds the CLT press. After placing each single-layer sheet, a glue applicator applies PU glue, which is health-safe and does not release harmful ingredients post-curing, ensuring strong cohesion in the final product.

The hydraulic CLT press consolidates the panels under high pressure, forming perfectly aligned cross-laminated timber sheets. Post-pressing, two suction spiders with overhead cranes handle the sheets, feeding them into a reversing table, wide belt sander, and CNC machining center to create ready-to-install construction elements. The fifth SSP-HD vacuum suction spider, designed for heavy loads up to 2.5 tons, handles the cut sheets using SPU suction plates. These plates provide high suction forces for both smooth and slightly rough surfaces.

Customized Vacuum Solutions

Schmalz has tailored all vacuum gripping systems at HolzBauWerk to meet specific handling needs. The lightweight aluminum components and high holding forces enable fast cycles. "Our extensive experience and numerous systems in Germany and abroad allow us to design effective solutions," says Philipp Bohnet, Head of Sales Systems at Schmalz. "Our test center in Glatten performs suction tests with customer samples to ensure reliability and facilitate seamless integration."

Since adopting Schmalz vacuum technology in September 2022, HolzBauWerk has praised the smooth transition from initial contact to operational success. "Our employees appreciate the automated and trouble-free processes provided by these systems, which have even been given names," remarks Jörg Kübler, Managing Director of HolzBauWerk Schwarzwald GmbH. He also values the proximity to Schmalz’s experts for quick support.