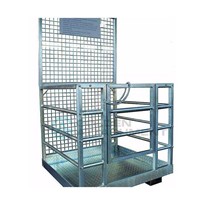

It is featured in the Australian Standard AS 1418:1, where a design is shown and which can be registered with the relevant authority for use in the workplace.

There are variations on the theme, such as fold-down types, doors placed on different sides, more open or closed mesh, handrails in different places. But they all conform generally to the Standard.

The King Safety Cage incorporates castors to enable the unit to be moved and stored easily. It is fully welded and shipped out with the rear top section as a separate bolt on item in order to save on shipping costs.

I am not a fan of folding or knock down kit units. They were designed to save on freight – which is a one-off event. From that point on it has to be assembled. If I’m up in the air in a cage which someone forgot to assemble correctly, or it moves around when I pull on the hand rails, then, well, call me old fashioned, but I like to be in something that’s really solid.

The King Safety Cage has two heavy duty steel loops onto which a lanyard is attached. The lanyard clips onto a full safety harness for those persons in the cage. The legislation states that if a safety railing is 900mm high, then a person is protected from falling. A safety cage has a 900mm high full surround (with internal hand rails and an inner opening sprung door), so it is deemed safe. HOWEVER, if I were sending one or two persons up in a cage, and IF that person reached out beyond the cage and fell, then I would be very relieved that the secondary safety device had saved their life, and allowed me and the operator’s family to sleep at night.

I recommend purchasing the Personal Protection Equipment (PPE) every time. Look upon it as cheap insurance. How much would it cost to insure an operator working at height if you approached your insurance company? For under a dollar a day, you know you have done your part.

Can you actually use a Safety Cage on your forklift or stacker? The Standard lays down parameters as to which types of forklifts and walkie stackers may be used. It relates to the capacity of the forklift, the tare weight of the cage and the maximum weight of the personnel and their tools or equipment. Not all forklifts and stackers are viable – mainly those in the lower load capacity – which are generally less than 1500 Kgs SWL. A sticker with the load limitations shown must be displayed prominently on every cage.

I have been asked to build safety cages outside the acceptable guidelines. Sorry, but I wont be a party to that.

I have been asked to re-sticker a rusted out safety cage. Sorry, but it needs to be scrapped.

Some bosses do not take worker safety seriously. For a few extra dollars they could buy the best and be assured they are legal and have a well made, long lasting product.

Safety Cages are NOT stock picking cages. They are designed to allow maintenance, painting, light changing, etc. With just a couple of hundred kilos available in load capacity, there is not much extra capacity for a load as well as an operator and the weight of the cage.

Operators must check that the cage has been well secured to the forklift (usually chains which wrap around the carriage and clip or shackle back to the cage, plus the fork sleeve extensions built into the cage, and have a pin which sits behind the heel of the fork tine) before they enter the cage.

Forklift drivers should position the cage directly beneath or as close as possible to the area the operators need to reach, without them having to reach out beyond arms length. Lower the cage when finished, then move to the next area and raise the cage again.

Moving personnel at height is not good practice if it can possibly be avoided. If it is absolutely necessary, get help as another pair of eyes on the ground at all times is beneficial, along with the area you are working in being roped off, with warning signs advising that work is being performed above.

The forklift plus cage should always move at a slow pace. The driver’s vision may be impaired due to the height of the cage and persons. Never raise the cage if the cage and forklift are not on level ground. Always be aware of potential hazards that may be above the person in the cage. There is a safety guard which will touch any overhead object (hopefully) first, but be aware of low hanging pipes, electrical wiring etc, prior to raising the cage, and always advise personnel in the cage to be aware of what’s around and above them, advising them to hail the driver if any impending danger is spotted.

-205x205.jpg)