According to the book, Slurry Transport Using Centrifugal Pumps, such downtimes are expensive, costing as much as $100,000 per hour. But, state-of-the-art pumps using the latest materials and hydraulics designs are proven to reduce downtime in mining operations.

The underlying principle

The durability of the suction liner is a key element in avoiding pump failure, and resulting downtime. Additionally, the probability of suction liner failure is directly correlated with the specific speed of pumps. Research shows that pumps with lower specific speeds have a longer suction liner life. Trained operators can match the operating cycle times of pumps to the cycle times and outages of the mill, thereby measurably reducing costly downtime.

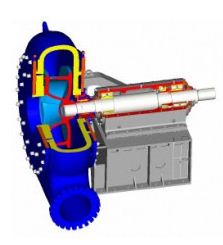

MDX pumps

The recently released GIW MDX pumps find application in mill discharge and cyclone feeds in hard mining operations. MDX pumps come in three models – MDX 64, 50 and 36 – with these varied operating specifications:

|

|

MDX 64 (24 x 28-64)

|

MDX 50 (18 x 18-50)

|

MDX 36 (10 x 12-36)

|

|

Flow

|

5905 - 7270 M3/HR (26k to 32k gpm)

|

2069 - 3546 M3/HR (9.1k to 15.6k gpm)

|

1090 - 1476 M3/HR (4.8k to 6.5k gpm)

|

|

Head

|

35M (115')

|

up to 35M (115')

|

22.5M (73.8')

|

|

Slurry SG

|

1.65

|

1.65

|

1.65

|

Features and advantages

As a new series of pumps, the MDX 64, 50 and 36 offer these advantages and key differentiators:

- Diverter impeller and liner stops and redirects the re-circulating solids.

- Lower specific speed design allows for greater operating range.

- 175-300 psi pressure rating makes the pumps thicker, stronger and hence last longer.

- Deep base circle increases volumetric area, reducing overall wear.

- Oversize shrouds enhance clearing vane performance.

- Patented inlet 5v impeller optimises the solids flow stream into the pump.

At the heart of the facility, the mill pump can reduce operating costs when pump operating cycle time’s match scheduled mill outages. The MDX series pumps are specifically designed for the hard rock mining industry - meaning fewer production disruptions and increased overall operational efficiency.

To learn how GIW MDX pumps can increase your mill productivity , please contact KSB Australia Pty Ltd, Brett Lewis, National Business Development Manager, Mobile:0408 202 585 or visit www.ksb.com.au