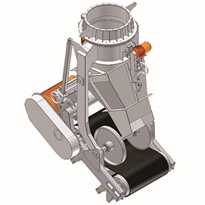

Pulse-jet baghouse dust collectors are commonly used in industries such as cement production, chemical processing, pharmaceuticals, and food processing. Pulse-jet valves are responsible for providing the pulses of compressed air that clean the filter bags in the collector.

What is a Pulse Jet Valve?

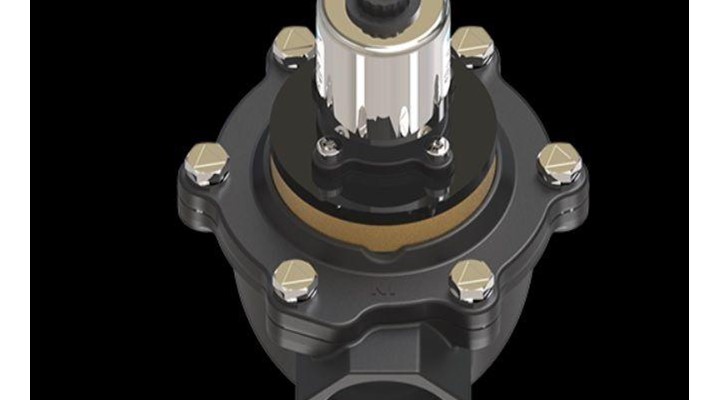

A pulse jet valve is a type of solenoid valve that controls the flow of compressed air in a pulse-jet baghouse dust collector. The valve opens and closes rapidly, allowing compressed air to be injected into the filter bags at high pressure. This pulse of compressed air causes the bags to expand and contract, dislodging the collected dust and other particles. The dust falls into a hopper, and the clean air is discharged into the atmosphere.

How Does a Pulse Jet Valve Work?

A pulse jet valve operates on the principle of electromagnetic force. When the valve is energized, the electromagnetic coil generates a magnetic field, which pulls the valve plunger against the spring. This opens the valve, allowing compressed air to flow through the valve orifice and into the filter bags. When the valve is de-energized, the spring pushes the plunger back, closing the valve and stopping the flow of compressed air.

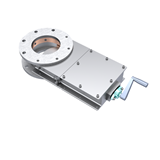

There are two types of pulse jet valves: diaphragm valves and piston valves. Diaphragm valves are the most commonly used type and consist of a flexible diaphragm that separates the valve body from the valve solenoid. Piston valves are less common and consist of a piston that moves up and down within the valve body to control the flow of compressed air.

Advantages of Pulse Jet Valves

Pulse jet valves offer several advantages over other types of valves. They are quick acting, which means they can open and close rapidly, allowing for precise control of the pulse of compressed air. This makes them ideal for use in pulse-jet baghouse dust collectors, where the pulses of compressed air need to be precisely timed to clean the filter bags effectively.

Pulse jet valves are also energy efficient because they require very little power to operate. This is because they only need to be energized for a short period to open the valve and allow compressed air to flow. Once the pulse of compressed air is delivered, the valve can be de-energized, reducing the energy consumption of the system.

Conclusion

Pulse jet valves are essential components in pulse-jet baghouse dust collectors. They provide the pulses of compressed air that clean the filter bags in the collector, ensuring the effective removal of airborne particles from exhaust gases. Pulse jet valves are quick acting, energy efficient, and offer precise control of the pulse of compressed air, making them ideal for use in pulse-jet baghouse dust collectors in a wide variety of industries.