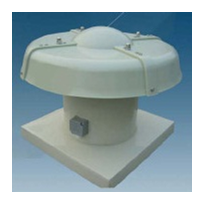

Hooded Roof Fans from Fanquip are manufactured in any of six common profile bases for fast and inexpensive installation often made by in-house personnel.

When problem situations in factories and assembly plants where everyday heat, dust or non-toxic fumes such as those from welding, forging, drilling, dipping, painting, etc, require solutions, Fanquip Hooded Roof Fans are strategically placed to force a controlled draft.

Roof exhaust fans allow the fast purging of dust affected internal environments in controlled fashion, thus ensuring a satisfactory work environment.

As the fans are supplied in any of six standard profile bases (corrugated iron, Trimdek, Super Six, Spandek, Double Rib & Span 4, and Longspan), retrofitting is normally a straightforward procedure.

Using a profile base, installation costs and time are cut by as much as 60 per cent and the unit can be installed by customers quite easily. No upstand is needed, while bindmesh protection is provided.

Should a roof profile not match any of the six profiles, a curb base is then used to accommodate the situation.

Made from fibreglass/alloy, Fanquip hooded roof fans are rated as heavy duty but they are lightweight and can withstand the force of extreme weather conditions and the threat of erosion.

Hooded roof fans are strategically placed at a significant distance from the major opening of a warehouse, workshop, storage depot, processing plant or other large complex so as to create an air flow dragged in through that main opening.

This achieves an intake of fresh air through, say, a set of rolladoors, with bad air drawn by and expelled through the hooded roof fans.

Normally heat or pungent odours are the reason for installation, but if dust is the cause of problems, this can also be extracted as easily as air or gases.

Motor speeds range from 720rpm to 1440rpm,with voltages in either single phase 240V or three phase 415V.

Specifications for each of the roof profiles are as follows:

- Corrugated iron profile

Fan diameters available are 400mm, 600mm and 1200mm with a free air volume from 1484L/s to 14000L/s. Motor power ranges from 0.18kW to 2.20kW.

- Trimdek

Fan diameters available are 400mm, 600mm, 800mm and 1200mm with a free air volume from 1484L/s to 14000L/s. Motor power ranges from 0.18kW to 2.20kW

- Super Six

Fan diameters available are 400mm, 600mm and 800mm and have a free air volume 1484L/s to 6800L/s. Motor power ranges from 0.18kW to 1.10kW.

- Spandek

Fan diameters available are 400mm, 600mm and 1200mm. Free air volume ranges from 1484L/s to 14,000L/s. Motor power ranges from 0.18kW to 2.20kW.

- Double Rib & Span 4

Fan diameters in this profile group are 600mm, and are capable of a free air volume from 3019L/s to 4300L/s. Motor power ranges from 0.37kW to 1.10kW.

- Longspan

Fan diameters 600mm and 1200mm, with a free air volume from 3019L/s to 14,000L/s. Motor power options are 0.37kW, 1.10W, and 2.20kW.

2-205x205.jpg)

-205x205.jpg)

-205x205.jpg)