Application

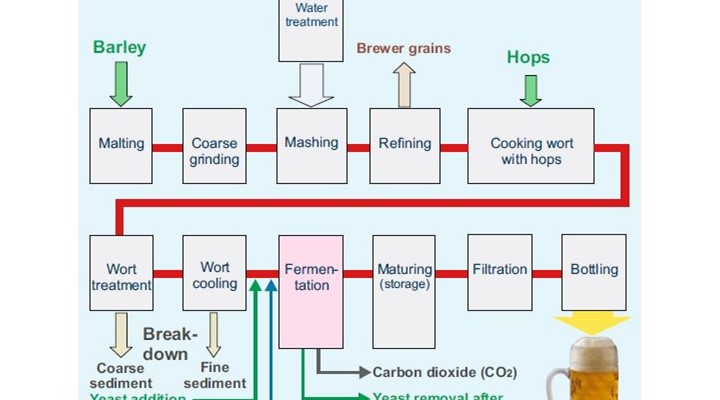

Nowadays, the most modern of hygienic processes are used to manufacture high-quality beer.

When manufacturing beer, both the knowledge of the art of beer brewing and a whole host of machinery and materials are needed.

Using various process steps, water, barley, hope and yeast are combined to make the drink which is supported by the German beer purity law.

The soluble, filtered extract gained from the malt when mashing is heated. This hot wort is cooled down.

The next important production step is fermentation. For this purpose, yeast and sterile air/oxygen is added to the cooled wort. The oxygen serves to activate the yeast cells. This green beer is piped into the fermentation tanks. The yeast attenuates the extract/sugar in alcohol and carbon dioxide, releasing heat. Moreover, the typical beer taste essences are formed during this major fermentation phase.

The extract content is virtually broken down are approximately seven days. The green beer is pumped into the storage tanks to mature and ferment further and continues to mature there at a temperature of approximately 0-1 degrees centigrade for approximately another three weeks.

The yeast deposited in the fermentation tanks in then withdrawn from the cone at the bottom of the container, washed and can be used for a new fermentation process in part.

Plant design

The feeding of the wort to the fermentation tank, the withdrawal of the yeast following the fermentation process, and shifting the green beer to the maturing tanks is executed using complex stainless steel pipeline systems. Various process variables are regulated in order to ensure adherence to the operating parameters. In particular the pressure in the fermentation tank which comes into being as a result of carbon dioxide build-up must be kept within precisely defined limits.

The saturation of the green beer with CO2 and hence the later beer quality is critically dependent on the pressure. On the other hand, if the pressure is too high it slows down the fermentation process. Excess CO2 must therefore be expelled in an orderly manner. It can also be fed into a CO2 extracting plant and is then available for use for other processes.

Solution

The feeding of the wort to the fermentation tank, shifting the green beer and emptying it from the storage tank later can be carried out using commercially available stainless steel butterfly valves.

GEMÜ 4222 combi switchboxes, which are attached directly to the valve actuators, are used for actuation and monitoring purposes. As well as the pneumatic pilot valves to control the butterfly valves, they also have an electrical position feedback to the control room.

The fermentation tank pressure regulation is carried out by GEMÜ 1436 cPos positioners/process controllers. The controllers are also adapted directly to the butterfly valve actuators. They are allocated the specification of set values "W" from the system control unit's PLC.

The GEMÜ 615 diaphragm valves with GEMÜ 1215 electrical position indicators can be used for feeding yeast and ventilating wort in smaller systems.

-205x205.jpg)