Setups and changeovers on a traditional press brake clamp are time consuming, frustrating and a significant drain on productivity. With each new setup, it takes time for operators to look for a hex wrench and then manually tighten set screws and seat punches. For shops that do numerous setups, downtime can add up quickly, resulting in lower productivity and lost revenue.

As the industry shifts more and more toward small batch processing, press brake fabricators need to find ways gain efficiency wherever possible. Adding a clamping system to a press brake can help speed setup times dramatically and reduce production costs.

Maximize Your Press Brake Flexibility

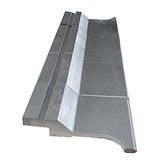

The Express Air Clamping System offers fast, flexible setups using a clean, low-cost power source. Designed for European style press brake tooling, Express Air is a pneumatic punch holder that uses standard shop air (90-120 Psi) to clamp and seat tooling in seconds with the touch of a button or the flip of a switch. There is no need for an additional pump or power source.

With a unique interlocking wedge design Express Air sectionalized punch holders can be pushed together to create a solid beam or gapped for box bending. They also boast the narrowest body on the market to enable the greatest range of bend angles — up to 30°with longer flanges in the front and back than similar holders.

Smaller Investment. Big Impact.

Additionally, if you have an older press brake that has a scratched, dinged or uneven bending surface, adding a clamping solution like the Express Air™ system will breathe new life into your machine. Not only will you get a smooth, harder work surface, you’ll boost productivity with a variety of timesaving features at a significantly lower cost than regrinding or replacing the beam.

Easy Installation

The clamping system is also fast and easy to install for minimal machine downtime. Additionally, the clamps are interchangeable with most OEM holders for a gradual transition to air power using several holders or all at once with holders for the entire length of the beam.

For faster setups and changeovers, add the Express Air pneumatic clamping system to your press brake and watch your productivity soar. For additional details, take a look at the table below or click here.

| TOOLING INFORMATION | |

| Tool Style | European |

| Seating | Beveled tangs self seat |

| Shortest Piece to Clamp | 0.394" (10mm) |

| Hardness | 70 HRC |

| Tool Shoulder Load (Symmetric) | 35 tons/ft, 104 tons/mf |

| Tool Weight Limit to Clamp & Seat | 192 lbs (288 kg) |

| CLAMPING INFORMATION | |

| Method to Secure to the Press Brake | American, Z1, Z2 |

| Power, Method, Actuation | Pneumatic, piston, wireless or handle |

| Beam Construction | Modular |

| Working Height | American and Z1 = 100mm; Z2 = 120mm |

| Operating Pressure | 90-120 Psi (6.2-8.3 Bar) |

| Clears 30° Acute Front and Back | Front and Back |