THE STARTING POINT

Esselte Leitz GmbH & Co KG belongs to the Acco Brands Corporation and is known for its file folders and innovative office supplies. The company offers its customers a 24-hour delivery service: orders received before 1 pm are shipped the same day. This requires the highest possible flexibility in terms of both personnel and deployment of equipment.

TIME-CONSUMING PROCESSES AND NUMEROUS ROUTES

Esselte Leitz ships 1.7 million order items annually and records six million goods withdrawals per year. This means that employees handle goods with a total weight of 40,000 tonnes. The company is therefore continuously working on optimising working conditions and making order picking highly efficient. In the course of this improvement process, the persons responsible modernised their existing concept for order picking and introduced the so-called Takt Time System. It allows shipments to be organised with as little effort as possible. In the course of this transition, the transport of goods by means of electric industrial trucks was also called into question.

Esselte Leitz wanted to significantly improve the utilisation of its technical resources and to reduce the time required for order picking. The aim was to be able to increase capacities flexibly, from one minute to the next. In order to achieve this, the company decided to use order picking trolleys that move under their own steam.

Since these weigh up to 400 kilograms when loaded, a solution was required that would make it possible to move and maneuver the heavy loads effortlessly.

OUR SMART MOBILITY SOLUTION

The heavy order picking trolleys need to be moved quickly without burdening the employees. At the same time, the trolleys should be easy to operate and have perfect maneuverability. We looked at the situation from several angles and considered various factors: the drive characteristics, the different requirements during the working process and ergonomic aspects.

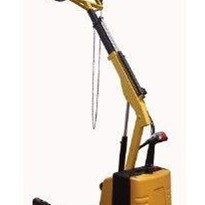

The solution: our e-drive electronic drive system, specially adapted in close cooperation with Esselte Leitz. The system has a powerful electric motor and makes it possible to set the order picking trolleys in motion at the push of a button. The speed is infinitely variable, both forwards and backwards. Employees can move heavy loads easily, quickly and comfortably. If no assistance is required, the

Drive wheel of the e-drive retracts automatically. The parameters of the control module and the battery life were adapted by our team to meet the specific needs of the customer. At the same time, we looked at the entire system and examined the optimisation potential of the existing castors. The selection of particularly low noise castors made it possible to significantly improve the driving characteristics of the order picking trolleys thanks to precision ball bearings and treads made of natural rubber.

Ergonomics also played a decisive role. We mounted the battery charging plug of the e-drive at the prefect working height and the hand-held control unit for the electronic drive system was ergonomically designed and installed at the optimum operating position. Esselte Leitz thus received a complete system solution in which all of the components are perfectly matched to each other.

OPTIMISED PROCESSES, REDUCED COSTS AND INCREASED PRODUCTIVITY

With the new order picking concept, Esselte Leitz‘s employees now have far fewer travel distances to cover during their work – 80 percent less, to be precise. The reduced use of industrial trucks also means that the company saves on repair, maintenance and training costs. Moreover, the highly efficient batteries of the e-drive´s drive system drastically reduce power consumption.