The information that management systems are able to collect from these field devices, such as diagnostic data, for example, status information on the devices and specific device parameters, can help the organization plan its predictive maintenance program. This information helps to prevent unplanned stoppages, reduces downtime and lowers maintenance costs. To enable plant operators to make the most of this potential for process optimization and cost reduction, the data delivered by all of the installed field devices must be both transparent and made available securely.

Data from the field directly to the tablet

To monitor and optimize manufacturing processes, an operations team uses analysis tools distributed via the cloud. All information from the

field devices, such as asset management, diagnostic and process data, is stored there in real time. Monitoring is visualized by means of a web interface and accessed via browsers preinstalled on tablets. No advance configuration, such as the installation of special apps, is necessary. The tablets are ready for use immediately. All data can be accessed in real time via an intuitive user interface. Maintenance personnel therefore has a clear and comprehensive overview of aggregated information at all times, and can use this to make informed decisions that speed up troubleshooting.

This is just one of the many possible application scenarios based on the pillars of Industrie 4.0 and IIoT. Growing volumes of data are being

exchanged by networked devices from a variety of manufacturers. Users and operators can benefit from this, and they don't even need to

become specialists in industrial communication to do so. The scenario described here will certainly be a reality before too long. At the moment, however, several technical challenges remain that automation technology still has to overcome before this example can be implemented in practice. What all scenarios have in common is the transparent integration of field device data into upper layers. This is the basis for all the further processing, analysis and visualization steps in downstream applications. To ensure the interoperability of different devices, open communication standards must be specified and used, and this requirement can be taken into account when new systems

are being designed. However, the situation with existing plants is different. Their communication architecture does not meet this basic requirement, which will be an integral part of future applications.

The current state of integration technologies

Due to the large number of proprietary solutions, various organizations and institutions quickly recognized the need for standardization and

developed integration technologies and techniques for data delivery based on open, protocol- and vendor-independent architectures that

would provide seamless interoperability and integration flexibility. Unfortunately, they were not able to agree on a universal solution. Today, users can choose from the following integration technologies, each of which has adopted a different approach:

EDD (Electronic Device Description) – a textual device description file

FDT/DTM (Field Device Tool, Device Type Manager) – a device driver with an integrated user interface

FDI (Field Device Integration) – an EDD with an integrated, optional user interface

All of these technologies have one thing in common: they are based on the traditional automation pyramid and are not transparent at all

levels. The data is collected from field devices via fieldbus or HART and converted in the SCADA level for use by applications. These technologies are based on software products that must always be installed on terminal equipment in order to establish a connection. There is no provision for further machine processing of the data. If any further processing is required, it can be done using specially adapted software, but this is certainly not standard.

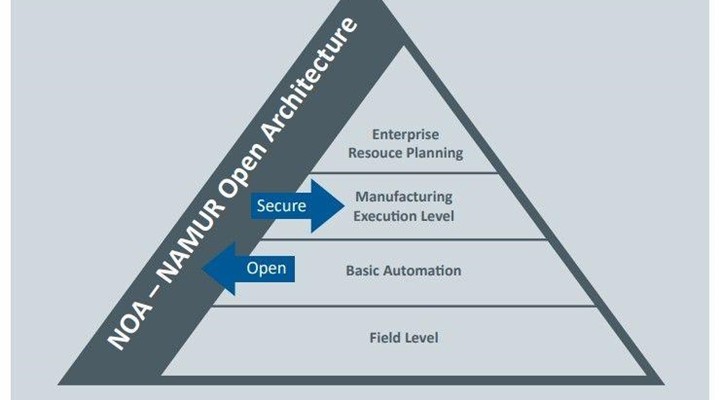

The conventional automation structure is often depicted as a pyramid with four layers. This structure has proven itself over many years and

offers a high level of operational reliability. On the other hand, it is not very flexible or open to the innovations and new technologies of the Internet of Things and Industrie 4.0. Namur Open Architecture (NOA) extends the existing structure by providing additional open interfaces. These also make the data from field devices and controllers available for higher-level monitoring and optimization.

The NOA concept allows both existing and new plants to make effective use of future innovations. The basic idea is to export data to the system via an open OPC UA interface from the previous automation world for monitoring and optimization purposes, leaving core automation tasks largely unaffected. Alternatively, a second communication channel can directly access information from existing field devices. NOA is currently being specified in the joint working groups of NAMUR and ZVEI. In view of this, more and more users and system providers are focusing on HART-IP. HART-IP, which has been part of the HCF Network Management Specification since June 2012, enables plant-wide, large scale solutions and offers a high degree of interoperability between devices and applications. The protocol runs over IP-based networks such as Ethernet and Wi-Fi and works over UDP and TCP with IPv4 or IPv6. The HART IP application layer is based on the same commands as the 4 to 20 mA HART protocol.

Implementing the Namur Open Architecture

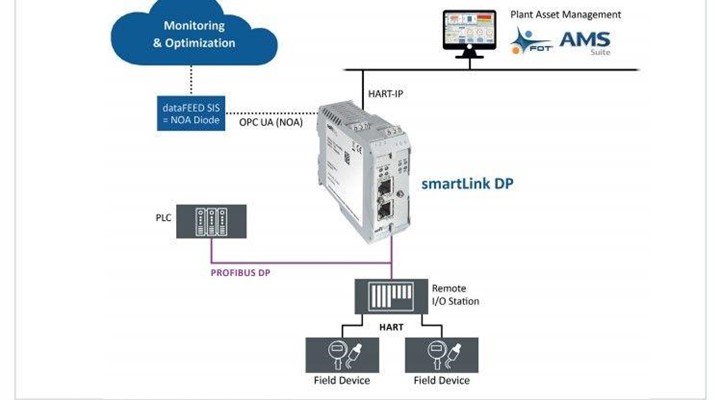

Devices make the open NOA interface available at various levels of the automation structure. The interface is based on OPC UA and uses

a standardized information model (NOA Information Model). Using an embedded OPC UA server, this information model can be implemented

by a remote I/O system, for example, a gateway or, in the future, directly by field devices with an Ethernet connection. For security reasons,

access to the data should be read-only. The NOA diode ensures that this is the case. With its smartLink DP, Softing offers a NOA-compliant gateway that collects data from HART devices via PROFIBUS remote I/Os and makes it available via OPC UA in accordance with the companion specification. In connection with a dataFEED secure integration server, which delivers the data unilaterally to the outside world, Softing already offers the functionality of a NOA diode.

Moreover, a HART-IP server integrated into the smartLink DP provides transparent access to HART field devices via Ethernet. In the future, it

will be possible to use any HART-IP client, such as Emerson's AMS Device Manager or ProComSol's Android app DevComDroid, to parameterize, monitor and evaluate HART field devices via this open communication standard.

In partnership with NAMUR and ZVEI, a demonstrator for the application case described was set up at Namur's Annual General Meeting from

November 7 – 8, 2019. The smartLink DP Gateway is scheduled for release in April 2020.

-160x160-state_article-rel-cat.png)