Hydraulic systems specialist Larzep Australia recently supplied a sophisticated laptop computer-controlled synchronous high-capacity lifting system to RCR Resources – Eagle for maintenance work on the base of a 6400-tonne Marion 8750 walking dragline at Wesfarmers Curragh mine in Queensland’s Bowen Basin.

The user-friendly system allows jacking accuracies of multiple cylinders to within 1 mm, and contributed to a very successful maintenance program on the dragline.

This project involved the Marion 8750 Series B tub being removed for maintenance, a world-first for the mining industry.

RCR Resources - Eagle, which provides construction and maintenance repair services to the Queensland and NSW coal industry was contracted to carry out maintenance work on the dragline over a 12-week period starting in July 2010.

Brian Lynch, RCR Resources – Eagle’s Senior Mechanical Superintendent, said the challenge for his company was to develop, in consultation with the client’s representative, the engineering to jack and level the machine after it had been stepped up to the ‘high cam’ position on the walking arms.

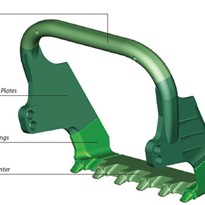

The machine had never been jacked and split for tub removal before, so a significant amount of effort went into engineering and installing a stiffening package in the front corners of the revolving frame on the dragline.

Two fully engineered jacking frames, each with a 1000-tonne working load limit (WLL) were used for this procedure.

RCR Resources – Eagle engineered and manufactured the jacking support frames, each of which housed two 500-tonne Larzep cylinders.

The remaining three of the seven jacks were fitted in custom-built jacking haunches at 120° around the circumference of the tub to allow for the lowering and raising of the tub during the removal/ installation phases, according to Lynch.

RCR Resources – Eagle opted for a modular lifting system from Larzep, which allows up to three high-capacity hydraulic power packs to be connected to a PLC controlled by a single laptop computer.

Larzep supplied the seven 500-tonne lifting cylinders for the tub lift-and-split along with an electric power pump incorporating valving controlled electronically via a PLC, all controlled by the laptop.

A further twenty-two 100-tonne capacity cylinders, also supplied by Larzep were purchased to complement RCR Resources – Eagle’s existing complement of 100-tonne cylinders, and were used to unload the dragline’s left-hand-side propel walking arm for later removal.

According to Duncan Bain, Larzep Australia’s Director, the company’s latest software allows an operator to control the lift using simple mouse clicks on the laptop. The application ensures all the cylinders lift and lower simultaneously to an accuracy of 1mm regardless of the load on each cylinder. It also has progressive lift control, providing the ability to tilt the load when required.

Larzep engineers were on site to supervise the commissioning of the lifting system and provided training on the new equipment.

In addition to the user-friendly Larzep software as well as smooth and controlled operation through the laptop, the RCR Resources – Eagle team were happy with the system’s ability to control an application involving many more cylinders.

This ability is particularly relevant for an application being developed by RCR, which will involve jacking the revolving frame from the tub for ‘planar’ alignment, so that reclamation machining works on the upper rail path can be carried out.

Bain said Larzep’s global experience in similar applications was key to the successful completion of the project.

The entire system, including the computer program was designed by Larzep’s engineering staff in its head office in Bilbao, Spain.

The modular system is designed so that a PLC can operate up to three separate hydraulic power packs, which in turn can have up to seven outlets. That provides up to 21 outlets from a system operating from just three power packs.

Larzep was able to manufacture and deliver the new system to site, within eight weeks of receiving RCR – Resources Eagle’s order.

Larzep Australia has established itself as a leading specialist in high-pressure hydraulics through its ability to supply high-capacity quality engineered jacking equipment.