How Magnetic Rotary Encoders Work & Measurement Principles

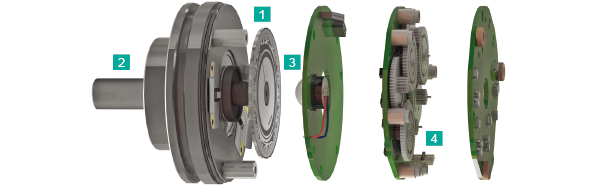

A permanent magnet (1) fixed to the encoder’s shaft creates a magnetic field that is sampled by a sensor (2) that generates a unique absolute position reading.

Signal Processing is the Key to High Performance

The technological leap that pushes POSITAL’s IXARC magnetic encoders to the performance level of optical systems is based on a new generation of sensor systems. The combination of a custom Hall-effect sensor and complex signal processing algorithms running on a powerful 32 bit microprocessor results in a considerably improved resolution and accuracy, along with latency times of only a few microseconds. POSITAL has also implemented an incremental interface and can now offer a complete range of encoder solutions.

Multiturn Measurement Technology

The Hall-Effect based sensor system is the singleturn stage of the absolute encoders. However, it does not enable the encoder to count revolutions if the external power supply is disconnected. POSITAL solves this problem by means of an energy harvesting system based on the WiegandEffect which requires no batteries or gears. Using batteries brings about a lot of disadvantages, since they have a limited lifespan, a considerable weight, and contain harmful substances. Gear units bring weaknesses of their own being large, complex, costly and vulnerable to shock and vibration. Regardless of the rotational speed, even at nearzero, the energy harvesting system generates short, powerful voltage pulses which supply sufficient power to the counting electronics in absolute encoders.Thus, the revolution counter is independent of any external power supply. This principle, which has proven itself since 2005, enables maintenance-free reliable measurement of absolute positions even in demanding environments for years to come.

Advantages of Magnetic Encoders

- Robust and durable

- Mechanically simple and economical − no battery, no gear

- Compact design for installation in small spaces

Multiturn Measurement Technology

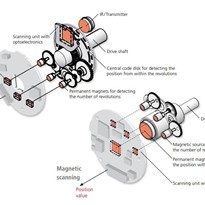

A key component of optical rotary encoders is a code disk (1) mounted on the encoder shaft(2) . This disk is made of unbreakable plastic that has a concentric pattern of transparent and opaque areas. Infrared light from an LED (3) shines through the code disk, onto an array of photoreceptors (4) . As the shaft turns, a unique combination of photoreceptors are illuminated or blocked from light by the pattern on the disk. For multiturn models, there is an additional set of code discs arranged in a gear train (5) . As the main encoder shaft rotates, these discs are geared together to turn like the wheels of an odometer. The rotational position of each disc is monitored optically and the output is a count of the net number of rotations of the encoder shaft.