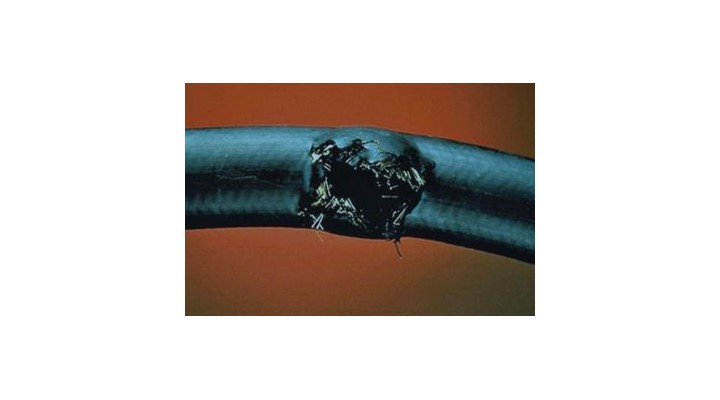

When a hose bursts, the fluid is released in an explosion of expanding energy. This release impacts the sleeve; the engaging fibres absorb the energy at the cross over points where the sleeve fibres are interwoven.

Hardy Spicer recommends that Hardy Spicer Protective Sleeve is firmly secured to the hose by a suitable clamping method.

Using the Hardy Spicer Protective Sleeving in abrasion protection applications will compromise the sleeve's burst protection properties.

Hose Burst Tests (Tested to 16,000 PSI burst: Testing conducted with 1/2" and 3/4" ID hoses) and Pin Hole Leak Tests (Tested to sustained 1mm 4000 PSI pin hole: Testing conducted with solid steel tube to ensure consistent 1mm pin hole) have been conducted using identical test parameters for both clamped and unclamped sleeves.

The test shows that the selection of the correct sleeve sizing is most critical to achieve optimum energy and fluid containment.

- Suppliers

- New to IndustrySearch? Book a Demo

- Advertise with us

- Login

- Email Marketing

- Buyers

- Get Quotes

- Articles & Ideas

- Login

- Subscribe to newsletter

- My Details

- Get Quotes

- Automation & Control

- Automotive Workshop Equipment

- Commercial Cleaning Equipment & Supplies

- Construction Equipment & Heavy Machinery

- Conveyor Systems & Components

- Electrical & Power Generation Equipment

- Electronic Components

- Farming & Agriculture

- Food & Beverage Processing

- Forklifts & Forklift Attachments

- Hydraulic & Pneumatic Equipment

- Industrial Materials, Tools & Components

- Industrial Pumps

- IT Hardware & Industrial Computing

- IT Software & Applications

- Laboratory Equipment & Instruments

- Manufacturing & Industrial Equipment

- Material Handling & Lifting Equipment

- Metalworking & Machining

- Mining Equipment & Machinery

- Packaging & Labelling Machinery

- Pallet Handling Equipment

- Personal Protective Equipment

- Security & Surveillance

- Test & Measurement

- Transport & Logistic Equipment

- Warehouse Storage, Shelving & Racking

- Waste Treatment & Environmental Management

- Welding Machines & Accessories

- Woodworking & Joinery Machines

- Workplace Equipment

- Workplace Safety Equipment

- Get Quotes

- Automation & Control

- Automotive Workshop Equipment

- Commercial Cleaning Equipment & Supplies

- Construction Equipment & Heavy Machinery

- Conveyor Systems & Components

- Electrical & Power Generation Equipment

- Electronic Components

- Farming & Agriculture

- Food & Beverage Processing

- Forklifts & Forklift Attachments

- Hydraulic & Pneumatic Equipment

- Industrial Materials, Tools & Components

- Industrial Pumps

- IT Hardware & Industrial Computing

- IT Software & Applications

- Laboratory Equipment & Instruments

- Manufacturing & Industrial Equipment

- Material Handling & Lifting Equipment

- Metalworking & Machining

- Mining Equipment & Machinery

- Packaging & Labelling Machinery

- Pallet Handling Equipment

- Personal Protective Equipment

- Security & Surveillance

- Test & Measurement

- Transport & Logistic Equipment

- Warehouse Storage, Shelving & Racking

- Waste Treatment & Environmental Management

- Welding Machines & Accessories

- Woodworking & Joinery Machines

- Workplace Equipment

- Workplace Safety Equipment

Trusted by 1,000,000+ Australian industrial buyers

Buyers

- Discover products & solutions

- Login

- Subscribe To Newsletter

- Browse All Products

- Read Articles

Suppliers

Advertise

- Promote your products & solutions

- New to IndustrySearch? Book a Demo

- Login / Forgot Password

- Advertise Your Products

- Success Stories

- Email Marketing

- Suppliers

- Advertise with us

- Login

- Email Marketing

- Buyers

- Get Quotes

- Articles & Ideas

- Login

- Subscribe to newsletter

- My Details

Get Quotes

- Automation & Control

- Automotive Workshop Equipment

- Commercial Cleaning Equipment & Supplies

- Construction Equipment & Heavy Machinery

- Conveyor Systems & Components

- Electrical & Power Generation Equipment

- Electronic Components

- Farming & Agriculture

- Food & Beverage Processing

- Forklifts & Forklift Attachments

- Hydraulic & Pneumatic Equipment

- Industrial Materials, Tools & Components

- Industrial Pumps

- IT Hardware & Industrial Computing

- IT Software & Applications

- Laboratory Equipment & Instruments

- Manufacturing & Industrial Equipment

- Material Handling & Lifting Equipment

- Metalworking & Machining

- Mining Equipment & Machinery

- Packaging & Labelling Machinery

- Pallet Handling Equipment

- Personal Protective Equipment

- Security & Surveillance

- Test & Measurement

- Transport & Logistic Equipment

- Warehouse Storage, Shelving & Racking

- Waste Treatment & Environmental Management

- Welding Machines & Accessories

- Woodworking & Joinery Machines

- Workplace Equipment

- Workplace Safety Equipment

Get Quotes

- Automation & Control

- Automotive Workshop Equipment

- Commercial Cleaning Equipment & Supplies

- Construction Equipment & Heavy Machinery

- Conveyor Systems & Components

- Electrical & Power Generation Equipment

- Electronic Components

- Farming & Agriculture

- Food & Beverage Processing

- Forklifts & Forklift Attachments

- Hydraulic & Pneumatic Equipment

- Industrial Materials, Tools & Components

- Industrial Pumps

- IT Hardware & Industrial Computing

- IT Software & Applications

- Laboratory Equipment & Instruments

- Manufacturing & Industrial Equipment

- Material Handling & Lifting Equipment

- Metalworking & Machining

- Mining Equipment & Machinery

- Packaging & Labelling Machinery

- Pallet Handling Equipment

- Personal Protective Equipment

- Security & Surveillance

- Test & Measurement

- Transport & Logistic Equipment

- Warehouse Storage, Shelving & Racking

- Waste Treatment & Environmental Management

- Welding Machines & Accessories

- Woodworking & Joinery Machines

- Workplace Equipment

- Workplace Safety Equipment

Trusted by 1,000,000+ Australian industrial buyers