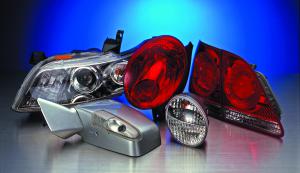

With a client base that spans all of Japan’s automakers as well as auto manufacturers from around the world, Ichikoh is under constant pressure to remain at the cutting edge of technology.

It has to manufacture a wide range of products with varied designs, and, all the while, reduce development time and costs.

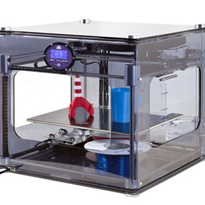

In 2007, Ichikoh embarked on a new process in which prototyping and mask creation took critical roles in ensuring mass production success.

The challenge

Ichikoh was seeking a cost-effective method that would allow it to evaluate new product designs before going into mass production.

"The design diversity of our headlamps and mirror products required extensive verification using actual products," Naohisa Akiyama, Chief Engineer at the Ichikoh Design & Development Headquarters, said.

"Without in-house prototyping, we often created molds only to discover that we had to repeat the process because of design problems."

Click here to read the complete case study