One that’ll support your excavator time and time again… Without cracking, bending or having your machine slip.

Is that too much to ask?

We certainly don’t think so.

This is why we’re going to break down the 3 most important things you need to consider before buying excavator ramps. We’ll also point you toward the right products for your needs.

But First, What Do We Know About Excavator Ramps?

At Ramp Champ, we’re Australia’s largest and best ramp retailer - selling over 3,500 ramps of all shapes and sizes per year.

And our CEO, Matthew, was formerly an operator in the civil construction industry. So you could say he knows a thing or two about alloy loading ramps.

Fed up with shopping around for a decent ramp himself, he created Australia’s first unbiased ramp retailer.

Construction machinery loading ramps were the first thing we stocked, and we’ve been growing our supply ever since. Sureweld, Digga, Heeve, AusRamp, Whipps… You name it, we’ve got it. So you can rest assured we’ll always put your needs first (rather than blatantly pushing the only product we’ve got lying around on the shelf).

So, ready to get stuck in?

3 Things You Must Ask Before You Buy An Excavator Ramp

How Much Does My Excavator Weigh?

It should go without saying that your excavator ramps should support the weight of your machine.

Sure, going for the cheaper option might be tempting at the time. But you’ll wish you had spent that little bit extra when you’re staring down the face of an empty job site. You know, workers twiddling their thumbs… unhappy clients… all because your ramps cracked under pressure (but hey, lucky it wasn’t any worse).

So when you’re buying excavator ramps, you want to make your decision based on the heaviest possible weight of your machine. This includes all the liquids (such as hydraulic oil and engine oil) as well as your attachments (bucket, grabs, hammers, rakes… you name it).

Whatever you plan on moving up and down the ramps should be included in your machine weight (yep, that could include you, too).

Take Luke for example.

Luke has a mini excavator with rubber tracks, and a minimum weight 1.75 tonne. He’s looking for a lightweight ramp option (because years of operating heavy machinery have left him with a crook back). Sure, he could just go for the lightweight ramp rated for < 2 tonne, but he decides to do some quick maths first. Smart guy. Luke’s excavator also has an expandable undercarriage, plus multiple bucket options including a heavy-duty bucket, digging bucket and mud bucket. Plus, when he stands on the scales, he’s shocked after reading 98kg (those after-work beers have been adding up). Then he adds on extras like gear oil, hydraulic oil, PPE, grease guns, chains and more. Before long, his mini excavator weighs more than 2 tonne!

Lucky he didn’t get that < 2-tonne option, hey?

He ended up going with the Heeve 2.5 Tonne Aluminium Loading Ramps. Perfect for rubber tracks and air tyres, plus it’s nice and lightweight for moving around. The best part? It’s a cost-effective and safe option.

What Length Loading Ramps Do I Need?

You can’t afford to get the wrong ramp length. You see, if your ramps are too short (steep) for your machine, it’s at risk of sliding or rolling. And not to mention the potential for serious injuries (or worse) to you and your workers. Yikes!

The ideal ramp length depends on the height of your truck or tipper. You see, we use the height of your tipper at the rear to calculate the ideal gradient.

But don’t worry, we won’t make you revert back to your high school textbooks on the basics of sin, cos and tan.

We’ve got a handy ramp calculator that does it for you. Just punch in the height of your truck or tipper and the length of the ramps you’ve got your eye on. Then, it’ll spit out the gradient in degrees.

As a general rule, we’re looking for a gradient between 16 and 23 degrees. The ramp calculator will also show a diagram so you get a good visual of how it will look.

Take Sally for example.

Sally is looking for a set of high-quality skid steer ramps. She has a skid steer loader weighing in at 2.5 tonne (after adding on all the extra weight like Bob). Her truck height is measured at 1.1m, so she needs alloy ramps long enough to get a safe gradient. She also hits the gym in her spare time, and rarely works alone, so the weight of the ramps isn’t a major concern. Sally has her eyes on the Sureweld 3-Tonne 3.3m x 550mm PT Series Aluminum Loading Ramps. She heads over to the ramp calculator and punches in 3.3m by 1.1m. You beaut! The gradient will be 19.47 degrees (which falls between 16 and 23 degrees) so Sally is in the clear.

Sally’s ramp choice is also designed and manufactured in Australia from structural grade alloy, plus it comes with a 12-month warranty (but we doubt she’ll need it).

What Ramp Rung Type Do I Need?

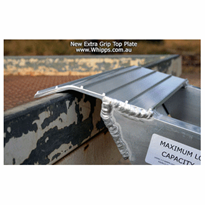

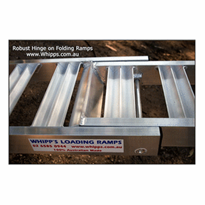

Does your machine have rubber or steel tracks? Asking yourself this question will make all the difference when you’re choosing alloy loading ramps.

To put it simply, steel track machines need ramps with rungs that are specially designed for steel tracks. Whereas rubber track machines need ramps designed for rubber tracks and rubber tyres.

In saying that, rubber tracks can also use ramps designed for steel tracks. So if you’ve got two types of machines (with steel and rubber tracks), you’d opt for the ramps with steel track rungs.

Loading a steel track machine onto ramps that are designed for rubber tracks and air tyres will spell disaster. You see, the opening and closing action of the steel tracks will chew right through your alloy ramps. And when the ramp breaks under this pressure, this won’t be covered under warranty… ahem, this one's on you.

So if you’ve got a steel track machine, it’s worth spending that little bit extra to get the right heavy-duty ramps.

Take Jason for example.

Jason has a steel track excavator weighing in at a whopping 6 tonne (after adding on all the extras), so he needs some sturdy alloy ramps to go with it. He also has a few smaller machines with rubber tracks that he uses from time to time. He thought about getting ramps with rungs for rubber tracks just to save a buck. But thankfully, he thought better of this idea.

Jason decided to go with the Digga 6.2 Tonne Ezi-Loada Aluminium Loading Ramps. They’re heavy duty yet lightweight, which helps to save Jason’s back after a long day. Not only that, they work for his 6 tonne steel track excavator as well as his smaller, rubber track machines. Great all-rounders.

So there you have it. The top 3 questions you must ask before you even think about buying machinery loading ramps. Asking these questions saved Luke, Sally and Jason from a whole lot of strife.

Do you need help choosing alloy loading ramps that are safe and get the job done? Ramps that’ll take care of your machine so you can keep plugging away?

At Ramp Champ, we’ve got plenty of ways to help. Visit our Machinery Loading Ramp customer form or use our Ramp Calculator. Or if you prefer to speak to a human, give us a buzz on 1300 913 047 or email us at hello@rampchamp.com.au

-160x160-state_article-rel-cat.png)