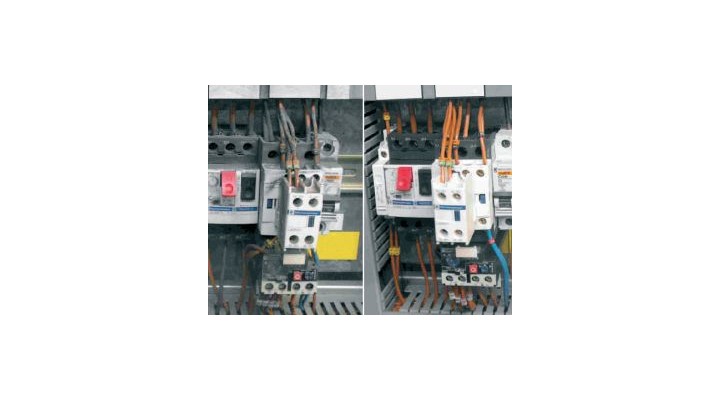

It can be used for cleaning: stator-rotor installations; turbines; transformers and substations; insulators; AC/DC motors; switchboards and electric cabinets; armatures, commutators and earth leak circuit breakers; nuclear decontamination; heat exchangers; and robotised and automatic cleaning projects such as nuclear power plants.

Dry ice cleaning is a method significantly faster and more efficient compared to any other cleaning system. Dry and non-abrasive cleaning leaves absolutely no wear to cleaned surfaces, increasing the life of all cleaned objects.

It is ecological and economic - dry ice leaves no trace and does not create any additional waste to be processed.

Testimonial

"We discovered CRYONOMIC as the alternative with significant technical, practical and economical advantages.

We are specialists in the maintenance of electrical power plants and are familiar with a range of both traditional and more sophisticated cleaning methods like abrasive blasting, the use of solvents, high pressure waterjetting, mechanical-, ultrasonic-, steam- and laser cleaning.

We were faced with the reality that most of these cleaning methods generate substantial secondary waste, could not be practically and economically implemented in our working environment, or required special protective measures. Most of these techniques can only be applied on a very restricted scale or are simply not suitable for cleaning in power plants.

We discovered CRYONOMIC Dry Ice Cleaning as the alternative with significant technical, practical and economical advantages. It's more rapid, dry, non-abrasive, non-explosive and non-toxic. Cleaning dead equipment poses no particular risk. When respecting specific safety rules and applying the right accessories and parameter settings, even cleaning live equipment can be done safely. In most cases the object to be cleaned or its surroundings need not be removed, closed down, specially protected or transported.

This commonly called 'in situ cleaning' creates enormous savings in terms of production time. Thanks to the sublimation of dry ice we do not create any secondary waste, a dramatic difference compared to our situation before.

Creating no secondary waste is specifically of substantial economic and ecological importance when considering assignments in nuclear power plants. We have chosen for the extensive experience and professional no-nonsense approach of CRYONOMlC, a partner we can rely on, even for consultancy on robotised cleaning."