- Touch: good epoxy powder has the same texture as silk, smooth and fluffy. While bad epoxy powder feels rough and heavy and is not easy to spray.

- The volume: the greater volume, the less impurities, the higher the cost, the better of powder quality. The smaller volume, the higher impurities, the cheaper the cost.

- The storage time: good powders can be stored for a long time (up to 12 months) whereas poor powders can sometimes only be stored for up to 3 months.

How to distinguish?

- Baking identification

There is not a lot of smoke produced by good powder during the baking process, while poor powder have a lot of smoke during the baking process.

- Identify by appearance or luster after baking

Good appearance of fine powder products, full, transparent, three-dimensional sense of strong. Poor appearance of the product powder dim, dull, misty surface, non-transparent, three-dimensional sense of difference between the two panels to observe the appearance of poor, Reputation, affect the appearance of the product. Glossy good powder gloss, can be a long time to maintain the relative luster. Poor powder gloss just baked out when the effect is good, a few months to start vector light. Of the material to make the powder can not maintain long-term stability of the gloss, the emergence of light, powder, stripping and so on.

- Adhesion and Aging Identification

Good powder adhesion, toughness, can keep a few years without powder, aging. Poor adhesion of the poor powder, very brittle, sprayed 3 months to six months after the start of aging, powder.Compared to the test adhesion And bending, and observe a few months after the product with or without aging, chalking. Adhesion and poor aging, the product easy to aging, chalking, rust, shorten product life.

- High temperature identification

The temperature adjusted to 220-230 degrees ,keep 10-15 minutes, good powder temperature and weather resistance is better, after high-temperature baking small change in color, gloss in little change. Poor powder have poor temperature and weather resistance, after high temperature baking serious discoloration, gloss dumb, this method is particularly effective detection of outdoor light-colored powder.

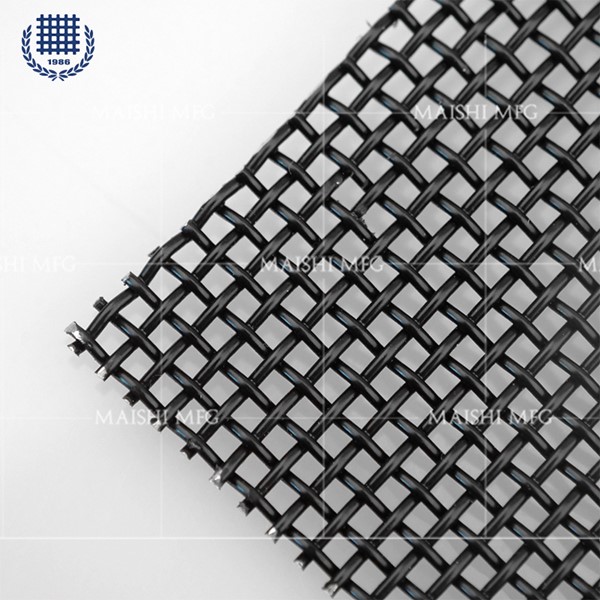

MAISHI GROUP use AKZO Nobel powder coating on our security screens, so the coating can remain 10 years no fade, fall-off and broken. You are welcome to send us inquires for your details.

-205x205.jpg)