The most technologically advanced self-propelled machines are now capable of reaching very high speeds when working in the most arduous conditions. This calls for a continuously increasing demand for high quality products and safe vehicle design lay-out.

How is SAI able to get around this and make safe transmissions?

1. CENTRE OF GRAVITY (C.o.G) anti-overturning: the wide range of products that SAI offers the Market, allows its customers to select the best solution for powering the vehicle.

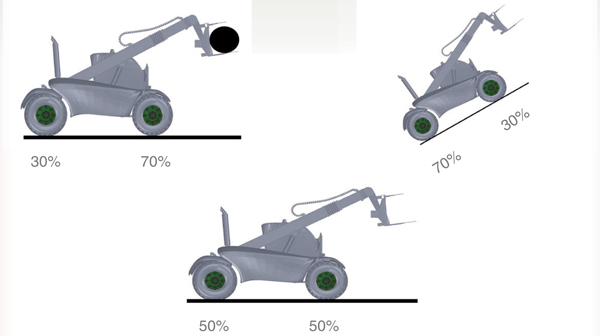

SAI wheel drive units enable the C.o.G. of the vehicle to be lower, resulting in more stability, even when operating a very steep slopes.

Overall vehicle performance is thereby improved, and the risk of overturning reduced. Furthermore, the redefinition of the vehicle layout and dimensions, thanks to the use of SAI wheel motors in place of a mechanical axle transmission, allows more flexibility of cabin design and engine position allowing for more comfort and safety.

Application example, orchard tractors: very compact and safe vehicles with lower cabin enabling access and operation under trees.

2. TRACTION DISTRIBUTION - Antispinning: controlling the traction means simply transmitting the available torque to the ground in the most efficient way possible.

Where vehicles do not operate safely due to wheel spin, the introduction of alternative circuitry, such as the inclusion of flow dividers or by connecting motors in series, are not the most efficient solution, nor do they give the fastest reaction times.

The best solution is to balance each individual wheel torque output to the torque transmissible to the ground. Thanks to the SAI variable displacement technology, a motor can vary its displacement continuously in full power, to reach every single wheel torque limit, even down to 0cc, to prevent spinning the wheel.

3. TRACTION CONTROL: safety is also a major factor with traction distribution. SAI variable displacement wheel drive units allow fine independent output torque distribution from every individual motor. By using a continuously variable wheel motor, the machine makes the most efficient use of the power available dependent upon specific soil conditions.

When manoeuvering on extremely steep areas, the operator must be protected to allow him to work under the safest conditions; in such cases, by using SAI variable displacement motors, it is possible to increase the displacement on the more heavily loaded wheels, thereby guaranteeing safe traction, even on slopes when heavily laden.

Therefore, it is possible to use the same power of the same flow setting on the vehicle, and to split it more to the front axle or more to the rear axle, as best required by the working conditions. All of the above results in much more efficient performance and safer operating machine.

4. ASSISTED BRAKING TORQUE: the continuously variable displacement motors produced by SAI, have extremely high mechanical efficiency that supply high levels of braking torque from the moment the vehicle starts to decelerate thereby guaranteeing rapid and controlled stopping. What is more, the operator can continuously, and with full controllability reduce or increase the displacement as required, therefore boosting the braking torque on any individual wheel, depending on specific needs.

5. AUXILIARY TRACTION: SAI motors used for auxiliary traction can work at high speeds by modulating the displacement. In so doing it is possible to use them for driving torque at low and medium speeds, whereas the motors can be set to zero cc/rev when being towed.

The motor can continuously vary its displacement while running providing variable power to be conveyed to the auxiliary wheels. The SAI speed capability makes it possible to work at the maximum speed limits allowable by Law.

IMPROVE THE PERFORMANCE OF YOUR MACHINES - MAKE THEM SAFE AND RELIABLE USING SAI VARIABLE DISPLACEMENT TECHNOLOGY!

Custom Fluidpower is the authorised Australian supply, service and repair centre for the complete range of SAI Hydraulic motors.Custom Fluidpower is a wholly Australian owned company offering hydraulic, pneumatic, filtration and lubrication product sales along with complete system design, installation and commissioning, and service and repairs.

Custom Fluidpower services the agricultural, aerospace, exploration, industrial, marine, mobile, mining and material handling industries Australia wide.

For further information visit www.custom.com.au.