Mission Foods is engaged primarily in the production, marketing, distribution & sale of tortillas, wraps, chips, flat breads and corn & wheat flour.

With operations spanning in Mexico, Unites States, Central America, Europe and Asia Pacific, Mission export to 50 countries worldwide and manufactures over 25% of the worlds flatbreads. A new state of the art facility, manufacturing and distribution, has been completed at Epping, Victoria.

The company entered the Australian market three years ago, following the acquisition of some local Mexican food distributors. The new location significantly expands production capacity to support its long-term growth strategy, and provides a host of manufacturing synergies and supply chain benefits, bringing several operations under the one roof.

Employing over 470 people, the 28,000 sqm integrated facility produces a wide range of fresh and frozen tortilla and pita bread products including wraps, pizza bases, corn chips and tacos.

Longest Colby Pallet Runner System

Supporting multiple production lines is a number of innovative Colby storage solutions that achieve high levels of space efficiency, productivity and safety. The longest Pallet Runner satellite storage system in Australia – storing pallets up to 55 deep – provides an efficient interface and buffer between raw materials and production.

Mission Foods’ Project Manager, Juan Marcos, explained: "Colby’s Pallet Runner is an excellent solution to our need to handle large quantities of pallet after pallet of the same product.

"It provides the best possible use of space, and gives us the ability to schedule and stage the bulk materials required for production runs.

"With Colby’s Pallet Runner system, stock is always on hand for production, and it also lets us put stock away at a convenient time," he said.

Highest Density Storage

Standing three pallets high by four pallets wide, with lanes extending over 100m long, the semi-automated system provides capacity for up to 840 pallets. Stock rotation is FIFO (first-in, first-out).

Combining the density of drive-in racking with the benefits of pallet flow, the Pallet Runner system uses self-propelled ‘intelligent’ carts to handle pallets within the storage system.

The Pallet Runner carts run on rails, which pass under each pallet location on each level of the storage system.

Unlike other storage system layouts, which require multiple access aisles, Pallet Runner systems only require aisles for pallet entry and pallet retrieval, making them very space efficient.

This enabled Mission Foods to store nearly twice as many pallets in a 2,800 sqm area between raw materials and production, than would have been possible using drive-in or other types of high density pallet storage racking.

Faster, Safer, Semi-Automated Pallet Handling

Because the Pallet Runner carts operate automatically and independently within the system, forklift operators are free to focus on bringing product to and from the racking, enhancing productivity and safety.

When pallets are to be put-away, the forklift operator first loads the motorised Pallet Runner cart into the relevant put-away lane, then loads the pallet into the lane. Upon receipt of the put-away instruction, the motorised cart drives under the pallet. A hydraulic lifting platform then raises the pallet, and transports it to the required put-away location within the lane.

By the time the forklift operator has placed the next pallet to be put away in the storage system, the Pallet Runner cart is ready to begin its next put-away cycle. Pallets are scanned as they are fed into the storage system, and scanned again when they are retrieved from the other end, providing real-time location ID and full traceability.

Deepest Colby Palletflo Helps Minimise Freezer Costs

The deepest Colby Palletflo Live Storage (PLS) system built to date helps minimise energy costs by maximising storage space efficiency within four large freezers, housing mainly finished goods.

Pallets of frozen goods weighing up to 1.2 tonnes are stored up to 16 deep on inclined roller tracks within the Colby Palletflo systems, which are up to three pallets high by 8 pallets wide. Pallets are loaded into the system from the rear, and roll gently forward until they reach the front face. When an empty pallet is removed, the next pallet of stock rolls into place, ensuring continuous stock availability and FIFO stock rotation.

Innovative Colby Storage Solutions

The project was implemented by Colby Storage Solutions distributor, Able Storage.

"Able Storage was a valuable member of the project team at all stages, and continue to provide great support and service," said Mr Marcos.

"They provided an innovative approach to solving our storage and handling problems, and Able’s team leader Bianca Humm was a great support throughout the entire design, specification and installation process."

"Even if some of our requests seemed a bit odd at the time," added Mr Marcos.

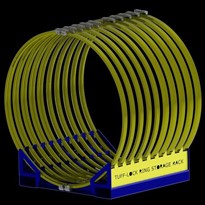

"Globally, all of our storage systems are painted yellow. So when I asked for our racking to be supplied in yellow, I think it may have been a first for Colby but, as usual, it was no problem."

Largest Single Project for Able Storage

Bianca Humm said she had enjoyed working on the largest single project Able Storage had tackled.

"We were supplying several different types of storage solutions over a period of more than nine months, and did our best to tie in with Mission Foods’ construction schedule."

"One of the benefits of being part of the Colby Storage Solutions network is that we have access to Australia’s most sophisticated rack manufacturing plant in Sydney. This gives us a very good chance of beating anyone else’s lead times when it comes to custom-design, quality, supply and value."

"Everyone at Colby is delighted to have played a part in helping Mission Foods get their new operation underway and wish them great success for the future."

Able Storage was recently named Colby Storage Solutions Distributor of the Year.