Application

The preparation of the cleaning and rinsing liquids takes place in a tank and cleaning takes place automatically and the cleaning result is documented in a cleaning protocol.

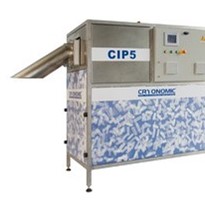

Plant design

The tanks and all medium wetted parts of the plant are made from stainless steel 1.4404 316 L.

The major components DI water and towns water are batched via a counting device, the cleaning liquids via dosing pumps. The liquids are heated by means of a heat exchanger.

A frequency controlled pump is used to transfer the cleaning liquid to the pipeline or tank spray head. Clearly defined cleaning programmes can be selected for the cleaning process.

Temperatures, times and cleaning media can be adjusted and therefore optimum cleaning for the various products can be determined.

All components of the plant and the control system are skid mounted and thus require little space.

Solution

A GEMÜ 625 pneumatically operated diaphragm valve with a T body is used for batching the DI water and its minimal dead-leg design is an advantage.

GEMÜ 625 diaphragm valves with a straight through body are used for dosing the cleaning media concentrates (acid and lye).

Monitoring is effected by proximity switches mounted on the valve actuators.

-205x205.jpg)