An effective coding solution tailored to your manufacturing requirements, can increase overall efficiencies within both your production environment and your supply chain. It must be robust, and offer the reliability and flexibility you need to meet the demands of a challenging manufacturing environment with ease. With this in mind, our resident coding experts have identified three key factors to consider when choosing the right coding technology for your environment.

Code Content

Since codes required for manufactured chemicals tend to be simple – often one or two lines – precise code placement and print definition may not always be key criteria when selecting a coding technology. A robust coding solution should be equipped to handle future changes to current requirements; whether this is changes to industry standards, increased code complexity, varying message code content for different customers, or printing text or codes in different orientations.

Substrate

In chemical manufacturing the substrate (surface) to be coded typically ranges from metal cans, to PET, PVC, HDPE, PP and other plastics, to flexible or rigid paper or cardboard. Whether you require a code to be printed onto a single or variety of types of substrates, our industry experts can provide recommendations and sample-code your substrates to ensure full compatibility for your requirements.

Production Environment

While controlled chemical manufacturing environments tends to be sterile and temperature controlled, other types of production environments can have an effect on the coder reliability and code quality. For example, if the environment is dusty or if wash down procedures are being performed. Consider the environment your coder will be working in, and whether an IP rated system or additional protective features will be required. Ensuring your coder has the required IP rating or protection will ensure optimal performance for the life of the coder in potentially harsh environmental conditions.

The Technology Line up

insignia offers coding and marking solutions suitable for every industry. The following technologies each have their own unique features for different applications and are ideally suited for chemical manufacturers.

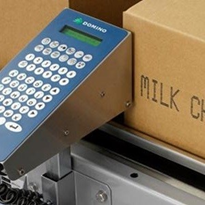

Continuous Inkjet Printers

Continuous Inkjet (CIJ) offers users a quick-drying, non-contact process. Codes are created by electrically charged ink drops, propelled at high speeds through the print head onto the substrate, creating a sequence of rounded dots that form a dot matrix code.

CIJ has earned its place as the preferred coding technology across a wide range of applications, due to its ability to produce high-quality codes at incredibly high printing speeds on a variety of surfaces. Specialty inks have been formulated for specialised applications, designed to withstand the harshest chemical manufacturing conditions.

CIJ coders are mechanically robust. All Domino Ax-Series CIJ coders are equipped with either an IP55 or IP65 rated stainless steel cabinet, enabling effortless printing for extended periods in harsh environments.

Benefits

- High-quality codes at high printing speeds

- Inks specially formulated to withstand harsh conditions

- IP55 and IP65 rated stainless steel cabinets

Print and Apply Labelling

Compact, reliable and easy to use, print and apply labelling (PALM) systems offer high speed carton and pallet labelling combined with fast consumable changeovers to ensure maximum productivity.

PALM offers the ultimate modular labelling system for your production line. With options for either standard or customised configurations to meet your production requirements, PALM offers the flexibility to meet your labelling needs.

PALM sets the standard for efficiency; the robust design and stainless steel cabinet is ideal for even the most challenging chemical manufacturing environment. The wide web applicator is designed to apply labels up to 8 inches in size, ideal for chemical drum labelling.

Benefits

- Customisation options for specialised applications

- Stainless steel cabinet ideal for challenging environments

- Wide web applicator ideal for chemical drum labelling

Large Character Coding

Large character coding is a robust and reliable solution, ideal for challenging manufacturing environments. Drop on demand valve technology produces consistent quality codes on a wide variety of porous and non-porous substrates.

The unique sealed printhead nozzle is capable of printing multiple lines of code in any orientation, and up to four printheads can be controlled from a single base unit. Print drop size can be adjusted depending on the substrate to be coded, offering optimal print quality for every application. Additionally, specially formulated fast drying inks are ideal for coding in harsh chemical environments, producing sharp codes with maximum reliability.

Benefits

- Multiple lines of code in any orientation

- Inks specially formulated to withstand harsh conditions

- Unique printhead nozzle ideal for tough environments