Where in the past they directly pack from under the blender, they now blend into bulk bags which separate the blending to the packaging process.

This has many advantages including independent scheduling on both operations.

Fresco Systems assist customers by fitting our bulk bag filling head under the existing blenders. Our single hand operated spout clamp and venting system enables quick and dust tight connection between the blender and the bulk bags. The bulk bags will then need to feed a form fill seal machine or any other packaging equipment. The packaging equipment usually provides a start/stop signal which is controlled by its weigh hopper.

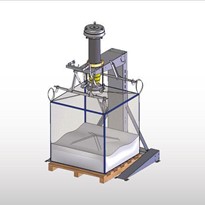

Fresco Systems supplies various types and combinations of this system into the industry and recently we supplied an electric hoist type unloader coupled with a flexible conveyor to feed pre-blended flour products into a form fill seal machine. Due to the various type of pre-blend that needs to be fed, Fresco Systems selected the beveled spiral flexible conveyor which is capable to handle difficult products which packs, smears and compacts.

This selection combined with the incorporation of vibration and agitation in the charging hopper ensures that the product flows consistently. A hinged hopper cover was also supplied to allow loading of smaller batch products. The start/stop signal from the packaging equipment communicates with our supplied control system which triggers and activates all the required flow aids above including bag massagers and the flexible conveyor.

Our experience and detailed system design ensures that the system was delivered, installed and commissioned with no hassles and all safety requirements to CAT 3 are met satisfactorily.