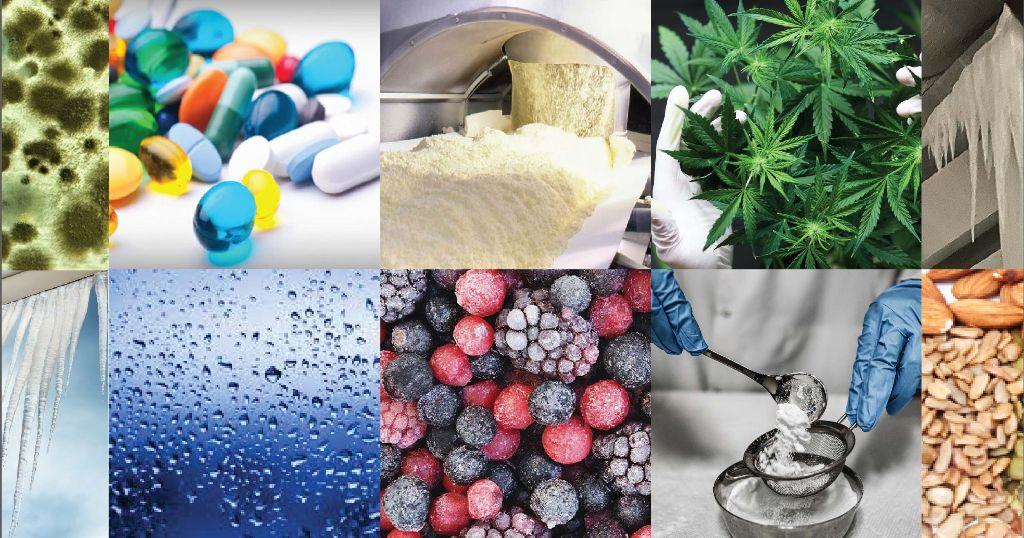

In this article, I highlight a variety of industries, their common moisture and humidity control issues and how dehumidifiers solve these issues.

Dehumidifiers can be used in a wide range of applications across a diverse range of industries. Depending on your specific needs, will determine whether you require a desiccant dehumidifier or a refrigerant (mechanical) dehumidifier.

BENEFITS OF A DEHUMIDIFIER

- Reduce mould, mildew and bacterial growth

- Increase productivity

- Increase product quality and reduce waste

- Decrease safety hazards

- Decrease operating costs

- Reduce energy consumption

How to Choose the Right Dehumidifier

REFRIGERANT DEHUMIDIFIERS

Many materials are more susceptible to moisture than they are to temperature. Self-storage units or warehouse storage facilities, dry rooms, swimming pools, museums, libraries, and archive rooms can benefit from energy-efficient air treatment solutions through combined humidity and temperature control.

They are highly effective for water damage and restoration and depending on the temperature, refrigerant dehumidifiers are useful in cellars and basements.

BENEFITS OF A REFRIGERANT DEHUMIDIFIER

Refrigerant dehumidifiers (also known as mechanical dehumidifiers) work in a similar way to refrigerators. It is an energy-efficient application that actually targets the moisture in the atmosphere.

Refrigerant dehumidifiers work best in spaces where the temperature is at 20° C and above and humidity levels of 50% and above. They work on the humidity of the room and run when the humidity is above its set point.

MOISTURE CONTROL

Common storage and preservation issues

- Corrosion and rust

- Mildew, mould, and fungus

- Bacterial growth

- Degradation of photographs and documents

- Storage / Cardboard boxes collapsing

- High energy consumption and cost

See the ‘PRESERVATION AND STORAGE’ section below for more specific benefits of a dehumidifier.

DESICCANT DEHUMIDIFIERS

Desiccant Dehumidifiers are ideal for controlling humidity and work well in any temperature.

If cold storage or process freezers are an integral part of your business, then a desiccant dehumidifier will eliminate any moisture control issues you may encounter. We have seen many cold stores and process freezers build up with ice, frost and condensation.

If indoor temperature is not your concern but you require low humidity, then a desiccant dehumidifier can create and maintain below 50% relative humidity regardless of the time of year.

HUMIDITY CONTROL

Common humidity control issues

- Production downtime

- Increased operating costs

- Increased safety hazards

- Increased energy consumption

- Loss of stock

- Corrosion on equipment and machinery

BENEFITS OF DESICCANT DEHUMIDIFIERS

Desiccant Dehumidifiers achieve humidity levels below 50% and have proven themselves to reduce operating costs and increase production. Desiccant dehumidifiers can maintain consistent humidity in all seasons.

CHOOSING THE RIGHT DEHUMIDIFIER

DEHUMIDIFIERS FOR COLD STORAGE & PROCESS FREEZERS

If cold storage or process freezers are an integral part of your business, then a desiccant dehumidifier will eliminate any moisture control issues you may encounter. We have seen many cold stores and process freezers build up with ice, frost and condensation, leading to equipment corrosion, water pooling on floors, frost on product and water damaged boxes. These then lead to production downtime, increased costs, energy consumption and safety hazards.

Benefits of a Dehumidifier in Cold Storage and Process Freezers

Dehumidification reduces the humidity levels in cold stores which contribute to condensation and frost. This is done by introducing dry air into the cold store and extracting the wet humid air. Low dew-point equipment removes the moisture before it can accumulate as ice on your equipment.

DEHUMIDIFIER FOR DRYING PRODUCTS

Drying out product is what dehumidifiers do. We have seen our systems solve moisture control issues in aging meat butcheries, vegetable drying stores and confectionary production. Each food type often loses quality and shelf life when they come into contact with air humidity that is too high.

These systems have also aided in the optimal growth of medical marijuana. Eliminating bud disease and root rot. Again, depending on your specific conditions, will determine if a refrigerant or desiccant dehumidifier is the right choice.

Benefits of a Dehumidifier for Drying

Moisture removal is controlled allowing drying time to be constant and consistent regardless of outside weather conditions. By creating and maintaining the optimal humidity and temperature level there is both less waste and increased quality.

DEHUMIDIFIERS FOR THE PHARMACEUTICAL INDUSTRY

In the manufacture of gelatin capsules and pan coating tablets, accurate humidity control is required to have maintain product consistency in gelatin capsules and so inconsistent drying in the rotating pan (for pan coating) doesn’t occur.

This is another application where, depending on your specific conditions will determine whether you require a desiccant or refrigerant dehumidifier.

Benefits of a Dehumidifier for the Pharmaceutical Industry

Dehumidifiers accurately control humidity levels. Dry air set at a specific humidity and temperature level will evaporate moisture in the pan and allow the coating to dry on the base.

DEHUMIDIFIERS FOR STORAGE AND PRESERVATION

Many materials are more susceptible to moisture than they are to temperature. Excess moisture in the air tends to degrade paper, cardboard, and books. Likewise, excess water vapour in the air is a real threat to the preservation of documents, artefacts, and relics.

Benefits of a Dehumidifier for Preservation and Storage

Depending on your specific needs a Refrigerant or Desiccant Dehumidifier is the most cost effective, energy efficient and stress-free solution. Both remove moisture from the air. Desiccant dehumidifiers produce dry air. The RH can be controlled, and a consistent optimal humidity level is maintained regardless of seasonal variations. Refrigerant Dehumidifiers work in a similar way to refrigerators. It is an energy-efficient application that actually targets the moisture in the atmosphere.

DEHUMIDIFIERS FOR SPRAY DRYING AND HYGROSCOPIC POWDERS

Dry conditions are the optimal climate for spray drying, handling and storage. Dairy to powder or protein powder manufacturers often encounter moisture control issues. Desiccant Dehumidifiers are the ideal solution for the manufacture, storage and transportation of hygroscopic compounds

Common Issues We Have Seen

- Quality is affected due to high moisture levels

- Extra manpower required to combat fluctuating humidity

- Loss of production in higher humidity months

- Operators have to constantly re-adjust settings because of humidity changes

- Very hygroscopic powders can be difficult to produce

Benefits of a Dehumidifier for Hygroscopic Powdered Products

Dehumidification physically removes the moisture from the incoming air. The dry air is in direct contact with the product during the process – so it is no longer affected by the weather. This allows for stable inlet conditions, enabling consistent quality and increased performance from the blowing or spray drying process.

DEHUMIDIFIERS FOR CANNABIS PRODUCTION

Cannabis is susceptible to a variety of humidity-related diseases such as botrytis, downy mildew and Alternaria.

Many growers maintain that soil and nutrients are the most important factors in growing cannabis, however, it is environmental conditions that really matter.

Light, temperature, air circulation, light reflection and humidity are the main factors for creating a perfect growing environment.

Benefits of Dehumidifiers for Cannabis Production

The relative humidity that is best for cannabis plants varies over the course of their lifecycle and RH levels should be changed during different cycles to optimise growth and health.

Dehumidifiers simultaneously improve grow quality, increase dry weight mass, and stimulates the manufacture of compounds.

At Humiscope we can design, supply and install all styles of dehumidifiers. We are the Australian supplier of choice for TFT Desiccant Dehumidifiers and HiDew Refrigerant Dehumidifiers (both high quality leading dehumidifier manufacturers based in Italy).

With technicians and engineers Australia Wide, we can solve your humidity control issues.

We are always happy to have a chat - obligation free - about your specific industry and any climate control issues you are dealing with.

-205x205.jpg)