However, they can also cause minor and sometimes serious damage to machinery and storage vessels resulting in production down time and even injuries to operators.

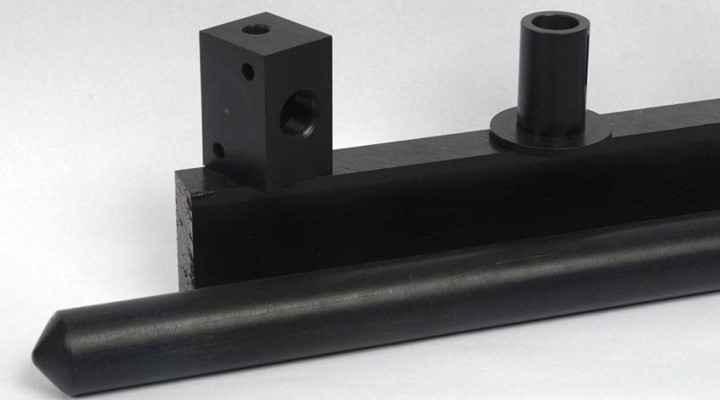

Engineering plastics such as nylon, Acetal, high density polyethylene can be machined to bespoke shapes which can minimise the risks of such collisions by avoiding metal to metal impact and acting as a buffer between the stationary objects in production facilities

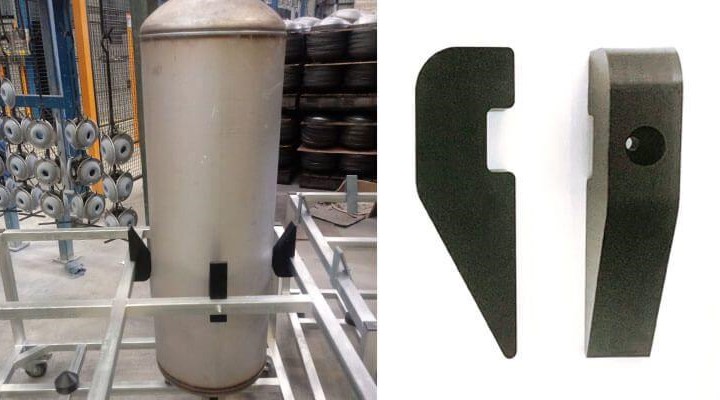

Recently the Allplastics Engineering division was approached by a major water vessel manufacturing plant where floor trolleys were causing damage to the vessels. Allplastics provided Acetal side guides to make it easy and safe for the operator to lower them quickly from above and stop them from wobbling around when they are being moved. The result was a pleasing one for the production facility allowing them to operate in a safer and more productive environment.

Let Allplastics provide you with solutions in your manufacturing facility and minimise wear of parts to improve safety, minimise downtime and reduce wearing of components.

Acetal properties

Acetal is a hard engineering plastic with high tensile strength and rigidity, excellent machining ability and versatility of application. Acetal has creep resistance and is resistant to hydrolysis, strong alkalis and thermo oxidative degradation. Acetal is suitable for use in components where exceptional strength is needed for above average temperature or moisture levels.

Key Features

- Excellent Corrosion resistance

- Excellent creep and wear resistance

- Excellent dimensional stability

- High lubricity

- High resistance to organic solvents

- High tensile and flexural strength

- Long term stability

- Outstanding abrasion resistance

- Recyclability

Availability

- Size (mm): 1000 x 610

2000 x 610

2000 x 1000

3000 x 610 - Thickness (mm): 3 - 100

- Colours: Natural, Black

Acetal Rods

- Lengths (m): 0.25 – 3

- Diameter (mm): 8 - 300

- Colours: Natural, Black