Solution:

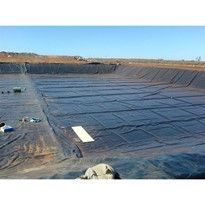

Absorb’s response was rapid. Using point-to-point road transport, it despatched one kilometre of floating booms and other equipment to the mine overnight. Both the equipment and an Absorb staff member arrived mid-morning to commence the recovery of the spill. The mine had also purchased several oil/water skimmers and pumps. Absorb’s expert supervised the use of the booms and skimmers with the mine team to maximise the rate of diesel recovery. The operation was under considerable time pressure as forecast rain threatened to flood operational areas if water could not be transferred due to contamination.

Result:

Within 24 hours, the spill response team had the situation under control with the majority of the fuel recovered.

Conclusion:

The risk presented by the fuel supply to the floating pump set should have been identified and reduced. For example, a double-skinned fuel line could have been used. As part of the mine’s risk management strategy, Absorb has also recommended the acquisition of a spill response trailer equipped with floating booms, an oil skimmer and an air-operated recovery pump together with Nationally Recognised Spill Response Training. Most mines are in the same situation and lack adequate spill response capacity on site. This incident highlights the need for all mines or quarries to review spill response training and capacity.