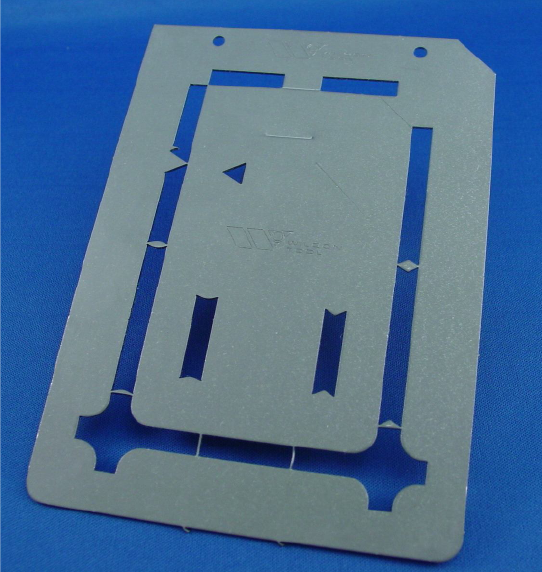

Most likely you have used tabs, or micro-joints, in one application or another in your shop. Tabs keep the part attached to the sheet which is then broken once it's removed from the machine.

The most efficient tab will keep a strong enough bond to the sheet to keep the part stable, but then break cleanly without requiring a secondary operation to clean up burs.

In reality, though, the most commonly used tab is a wire tab. Wire tabs are the weakest and most unstable form of tabbing. They don't break cleanly but leave a sharp edge on your parts, requiring the parts to go through a secondary de-burring operation, which is inefficient and time-consuming. Fortunately there are several other techniques for making tabs that may work better and more efficiently.

Depending on your application, there may be a situation where a wire tab is your only choice, but more often than not, there is a better option available to you. Give one of these 7 tabs a shot - we think you will be pleasantly surprised with the results.

(10)-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)