In a highly competitive marketplace, businesses need to consistently look at new ways to work smarter in manufacturing plants to increase outputs, improve efficiency and, as a result, boost profit. Checking in regularly with your current processes and driving improvement in all areas of your business can help you save on manpower, so these key resources can be used elsewhere in the business.

These are our top three tips that can help you create a more effective and efficient manufacturing floor. Remember, before you implement any changes you should first measure your existing output so you have a baseline to assess against that will allow you to determine if any changes you made worked.

- Get smarter with technology

Technology has revolutionised the world, and yet many manufacturing business owners haven’t embraced it to its full extent to streamline business practices. If used effectively, technology can increase productivity and save business costs in enormous ways.

Take, for example, the usefulness of online shopping or e-purchasing. With the day-to-day demands of running a business, it can be difficult to find the time and resources to travel and purchase necessities for the workshop. Spend your highly valuable time where it counts and make the process easy by ordering products online. It’s as easy as picking up your mobile after hours, selecting what you need and processing the payment. Your order can be conveniently delivered to your warehouse door within a couple of days.

The digital space allows you to order outside of local suppliers, so look for services like ovesco’s online store so you can order anywhere in the world.

- Tools and equipment that raise productivity in your manufacturing warehouse

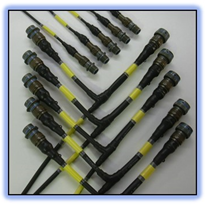

Your warehouse must have the best machinery, devices, equipment and tools that drive error free results in the shortest timeframe possible. Investing in quality equipment that produces quality results and requires minimum staff training will reduce the time your staff need to spend on that equipment and precious time wasted on machinery breakdowns. An efficient manufacturing floor should be devoid of costly downtime and should have standardised and simple systems for quality control.

For example, investing in a high-grade industrial fastener, such as the Huck BobTail, will simplify work. Automatic Huck BobTail fasteners can be installed in as little as two seconds with a four-step process using a special hydraulic tool. Installation with no pin break means less debris falling to your shop floor, which results in a more efficient clean up.

- Focus on continually improving your processes and systems

For companies seeking large-scale operational progress, continuous improvement should be at the heart of your business. Consider:

- Reviewing the processes that other businesses in your industry use to determine if you need to make changes to your own systems.

- Continually attending industry education and development opportunities so you can be aware of new processes and technologies first.

- Seeking external help from an expert who can perform a SWOT analysis on your business and identify solutions to current productivity issues. Or consider employing someone internally to perform this role.

Accelerating your productivity through these key tips can help you create a lean, efficient and effective manufacturing floor for better profit and results.

-720x400.jpg)

-720x400.jpg)

-160x160-state_article-rel-cat.png)