Alongside simple screw caps, we use trigger heads to spray surfaces, safety caps to protect children, and a growing range of other types. Each container cap has its own nuances that create challenges for capping machines.

While it is almost impossible to describe every type of cap in a short list, here are the thirteen main types you may encounter. Understanding these will help you select the perfect option for your product while ensuring your capping machines take them in its stride.

Standard Screw Cap

Standard screw caps and lids are the most familiar type, although there are many variations. The main purpose of these simple caps is to allow users to unscrew and pour out the liquid before screwing them tight again. Often made from plastic or aluminium, screw caps preserve a range of products, from soft drinks to jars of honey and small medicine vials to large chemical drums. Some screw caps include a ‘pilfer proof’ seal around the neck of the bottle that breaks with the first twist. Many also include a foil or plastic seal stretching across the open neck of the bottle or container. This helps prevent leakage and tampering and keeps the product airtight and fresh during transportation.

Child Proof Caps

For potentially dangerous products, such as medicines, chemical cleaning products, and motor oils, this screw cap’s safety mechanism prevents children from opening the bottle. To open safely, you push down and twist the cap or squeeze the sides. Naturally, your automatic capping machine will have to cope with this type of closure.

Flip Top Caps

Another screw cap variant is the flip top lid, often used for squeezable containers stored cap downwards. Some products using this type of cap include shampoos, toothpaste and sauces. The caps include a small hole in the centre of the lid, allowing the product to flow, with a flip lid that closes to keep the contents fresh. Like standard screw caps, flip tops may include an inner foil or plastic seal. Flip spouts are similar to flip top lids, but only a section of the cap flips upwards to provide a useful nozzle for directing the product.

Disc Top/Press Top Cap

The disc cap is very similar to the flip top, but you depress the disc on one side of the cap, and the other side pops upwards, revealing the hole for releasing the product. Disc top caps are common for shampoos, face creams, sun creams, and other personal care products, partly because they are easy to open with wet or greasy hands.

Sports Caps/Push-Pull Cap

Sports caps are a screw top cap variation that incorporates a shaped nozzle pointing upwards that you pull to open and release the product. They are common for sports drinks because you can engage the nozzle with your teeth while jogging or cycling. Most include a plastic protective cap to cover the nozzle.

Trigger Heads

The ubiquitous trigger heads are familiar, allowing you to squeeze the trigger and release a jet or spray of a product. They are common for cleaning products, such as window cleaner and bathroom spray, and garden products such as weed-killer and plant food. Most include a locking mechanism where you twist the nozzle or the entire cap to prevent accidental discharge. Trigger heads are common, but they can be tricky for capping machines to handle because they need side tightening. These caps also have a habit of jamming hoppers and feeding mechanisms.

Spray Caps

Spray caps or heads, also known as atomisers, are familiar additions to perfume bottles. You simply press the cap with a finger, and the product emerges as a fine spray or jet. Most spray caps are plastic, although luxury goods can use metal caps. Naturally, to protect the caps and prevent accidental discharge, most products contain a separate plastic or metal protective cap that fits snugly onto the bottle. One variation includes pressurised aerosol containers, such as deodorants, where the nozzle fits onto a plastic tube.

Pump Caps

Pump caps contain a dispenser that discharges liquid or cream when depressed, and twisting the pump locks it in place. They are popular for hand soap and sanitiser because they minimise contact, and for shampoo and sunscreen. Like trigger caps, they can be unwieldy and pose problems for capping machines and feeders.

Beer Bottle/Crown Caps

A capping machine fits these metal caps over the neck of a bottle before crimping them into place, providing a cheap and easy way to keep drinks and beers carbonated. Opening requires a bottle opener to flip the cap off, and it usually cannot be re-tightened.

Twist Top Cap

Twist top caps are usually conical with a hole at the top that allows the product to flow when you twist the nozzle to open the hole. Twist tops are common for sauces, especially mustard.

ROPP Caps – Roll On, Pilfer Proof

ROPP caps are useful for products where tampering can be a problem, such as spirits and liqueurs, and provide an airtight seal for sparkling wines. With this system, the capping machine presses a blank aluminium cap on the threaded neck of the bottle for a tamper-proof seal.

Corks

Corked bottles are familiar, especially to wine connoisseurs. Made of cork or plastic, a capping machine uses pressure to push the cork into the bottle for a tight seal. For most products, machines then apply a plastic shrink-wrap sleeve over the neck and top of the bottle.

Eye Dropper Caps

The eyedropper cap, used for medicines, eye drops, ear drops, and essential oils, includes a glass or plastic dropper pipette that extends down into the bottle. The cap incorporates a bulb that the user squeezes to dispense the product.

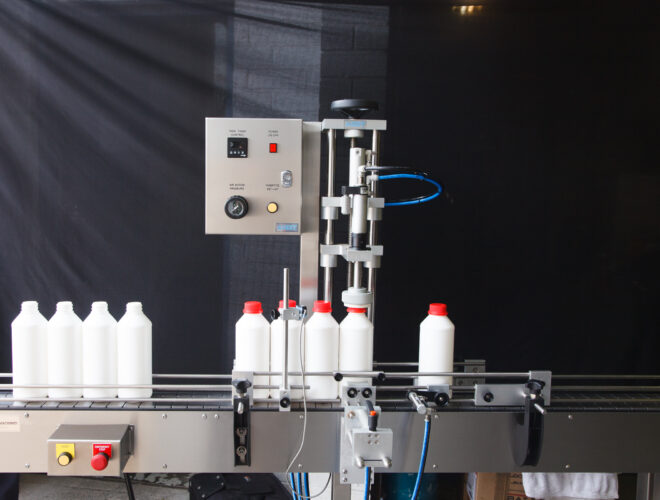

Integration With The Right Capping Machine

While these are some of the main types of caps for bottles, there are many more variations that businesses may encounter. No matter what bottling business you operate, you need a capping machine that easily integrates with your production line. And if you operate multiple product lines, then your capping machine must be able to switch seamlessly between different types.

Asset Packaging Machines’ capping systems are highly flexible and allow you to change between standard screw caps, which need tightening from above, and trigger caps which need side tightening. Swapping between the various types simply requires changing the chucks and adjusting a few parameters.

Our machines can also integrate with other technology, including filling machines and conveyors. Manufactured to our usual high standards, our Australian-made machines are robust and easy to clean and maintain. If you want to try out the technology, we even offer capping machine hire.

-160x160-state_article-rel-cat.png)