The new facility is the result of the consolidation of the Spearwood OneSteel Metalcentre, the Midalia Steel Welshpool warehouse and two other smaller warehouse facilities. It has been touted as being one of the most modern and unique steel warehouses in the country.

According to OneSteel Metalcentre WA State Manager Michael Hurley, a major benefit of the new DC is its greatly enhanced materials handling capacity.

"Thanks to the design and new technology in this facility, we have the capability to provide a much higher level of customer service via productivity efficiencies, extended range and stock holdings," said Hurley.

Engineered to hold a large range of OneSteel and Midalia Steel products, including a new range for the oil and gas sector, these technological innovations underline the company’s commitment to better serving their customers.

"The distribution centre's innovations allow us to hold a larger quantity and a more diverse range of steel product, while at the same time reducing the risks on projects and maximising the quality of results," said Hurley.

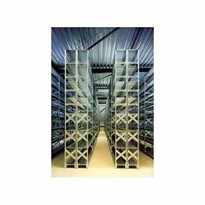

The backbone of these innovations is the German-made Kasto computer controlled storage system that has been designed to provide a range of inwards and outwards materials handling capabilities.

"Nothing of the scale of this Kasto system currently exists in Australia – it is truly unique to OneSteel Metalcentre here in Perth," said Hurley.

Utilising a special honeycomb-style storage system, this particular Kasto structure can support 2272 cassettes that are able hold a maximum of 11,000 tonnes of steel at full storage capacity.

The Kasto system is designed to automate picking and packing, with each cassette holding up to five tonnes of steel at a maximum length of nine metres each.

"With an exceptional ability to pick accurately and efficiently, reduce stock damage and weigh steel product upon receipt and/or dispatch, the Kasto system is a real feature of our new DC," said Hurley.

"There are a range of added Workplace Health & Safety advancements provided by the Kasto technology - the fact that humans are now removed from the steel handling process goes a long way in helping to improve safety."

From an engineering perspective, the entire honeycomb structure that holds the Kasto system was erected like a big Mechano set, with several thousand bolts drilled into the foundation to hold each of the structures’ vertical uprights with anchors to secure these uprights into the foundation.

Once the honeycomb 'end-block', which acts as a strengthening block for the entire structure was completed, the rest of the structure went up relatively quickly.

After the internal storage configuration was complete, the entire structure was finally clad with steel sheeting.

Together with the installation of the Kasto system, the new distribution centre also required the re-installation of the original capital equipment items, including two High Definition (HD) Plasma machines, one Oxy Profiler machine, a FICEP Beamline, one FICEP Bandsaw, along with a brand new drill and bevel machine.

"Due to the Kasto storage system and the expanded space, we are able to provide enhanced efficiencies, better levels of customer service and an unprecedented level of safety, making the OneSteel Metalcentre Perth Distribution Centre an example of the best in state-of-the-art steel storage and handling," concluded Hurley.